extensive starch-moulded confectionery applications:

Gummies and jellies, marshmallows, nutraceuticals, fondant creams, liquorice, crusted liqueur and more.

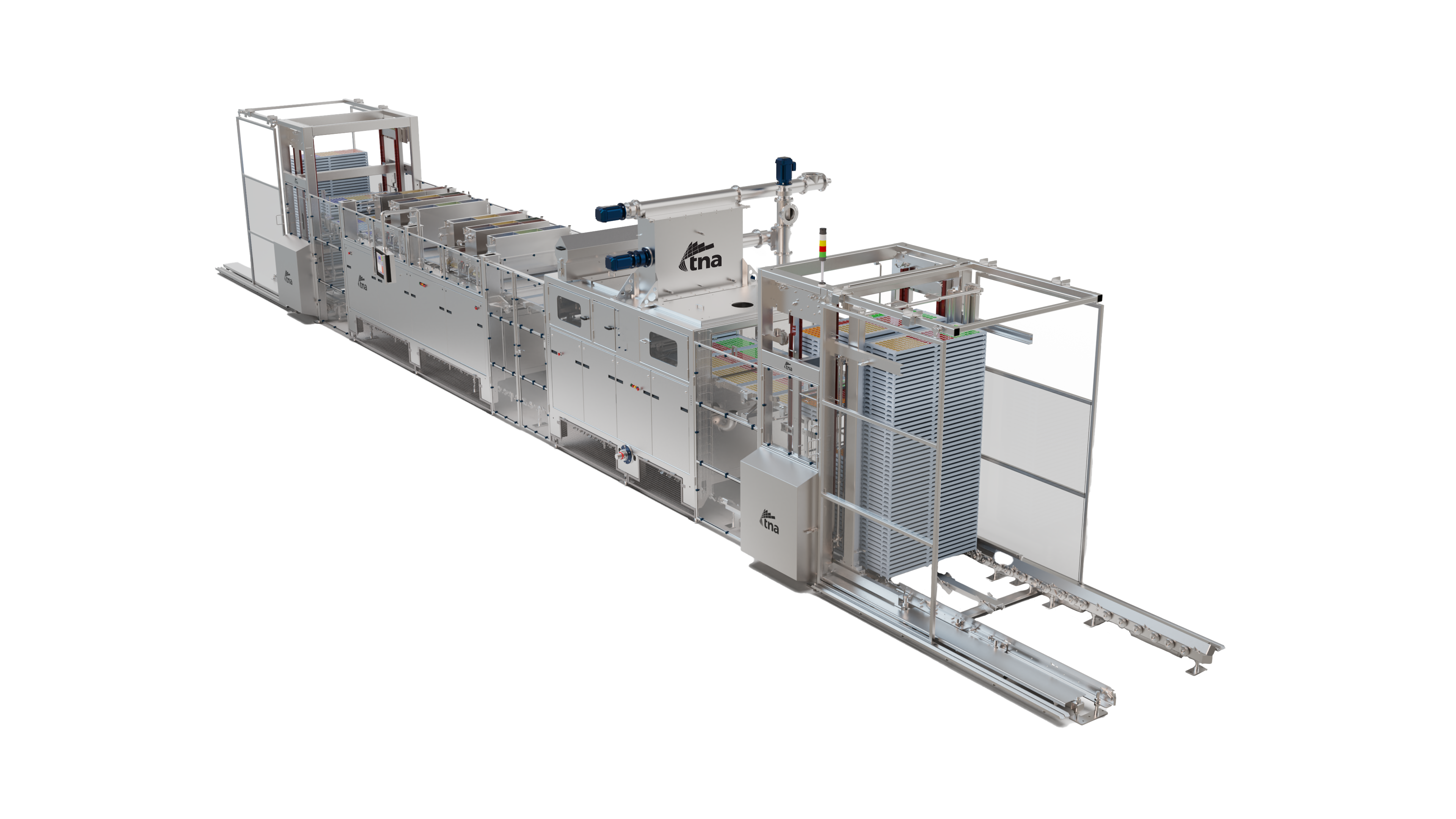

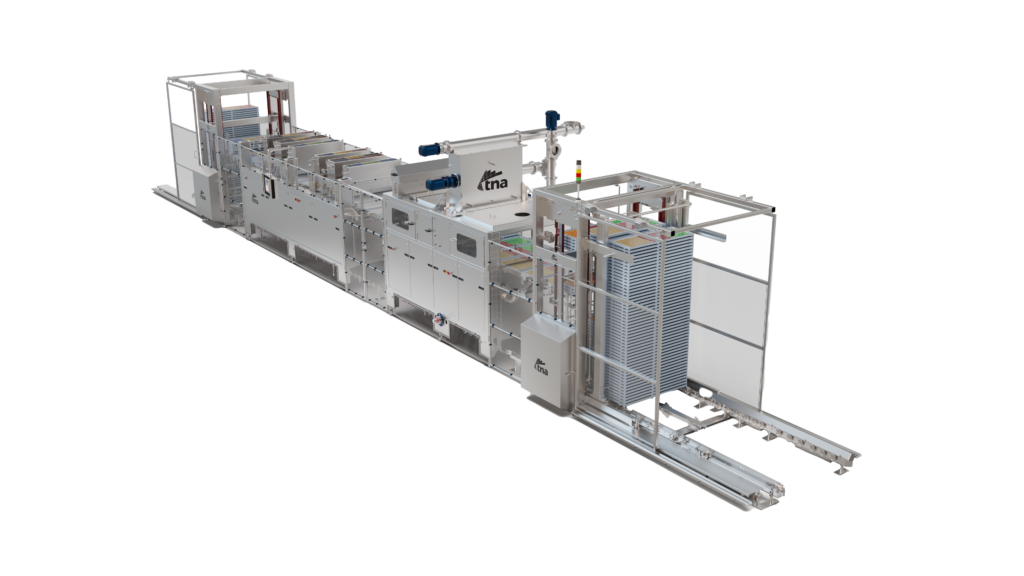

tna mogul ST

The tna mogul ST is a high-performance starch mogul designed to effectively mould a wide range of confectionery products, including gums, jellies, marshmallows, fondant cremes, centre-in-shell, nutraceuticals and liquorice. Featuring an all-in-one fully integrated feeder, starch buck, depositor, stacker and pallet transport system, the tna mogul ST offers a complete starch moulding solution. Choose from a variety of pump modules to deposit in single-colour or two-and three-colour combinations, including side-by-side, foam and starlight.

With a simple stainless-steel construction that adheres to the highest hygiene and safety standards, including ATEX, you never have to compromise product safety or factory cleanliness. In addition, the tna mogul ST enables continuous operation outside of routine maintenance, processing up to 35 trays per minute*.

*Trays per minute, subject to product type, shape and mass.

tna mogul MX

tna mogul MX, designed for the larger tray, provides a maximum capacity of up to 4,500 kg/hr, depending on a specific product size, piece weight and starch conditions.

The tna mogul MX fully integrates the automatic tray stack feeder, starch section, depositors, tray stacker and pallet transport.

With unsurpassed versatility in product variation, the moguls accommodate a wide range of depositing pumps and suit a wide variety of starch-moulded products.