As part of TNA’s journey to deliver complete solutions to the food industry, the acquisition of NID brought world-class expertise in starch moulding and confectionery production into the family.

For decades, NID has been a trusted name in the confectionery industry, known for its innovation, precision, and reliability in moulding technology.

Today, under the TNA brand, this legacy continues – helping manufacturers create high-quality confectionery products with new innovations, efficiency and consistency, while being supported by TNA’s global network of experts.

With precision retrofits and premium upgrades, TNA aftermarket care keeps your tna mogul (formerly NID) running stronger for longer — delivering reliability, efficiency, and lasting return on investment.

Book a machine audit to unlock the full potential of your equipment. It’s the first step toward optimising confectionery production performance, reducing downtime, and future-proofing your production line with tailored upgrade solutions.

Retrofits and upgrades

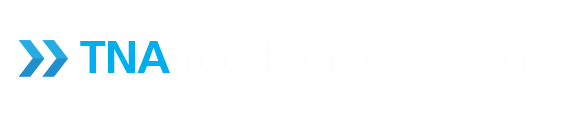

Tray insert eject station

Allows inserting and ejecting trays from the line while the tna mogul continues production. Each module is designed to insert and/or eject a sub-stack of trays and can be designed to work in combination with Vision or Tray weighing systems. This upgrade can be retrofitted into older tna moguls if sufficient space is available.

Depositing station

Includes a depositor pump and all essential equipment, enabling you to diversify your product offerings and expand your production capabilities.

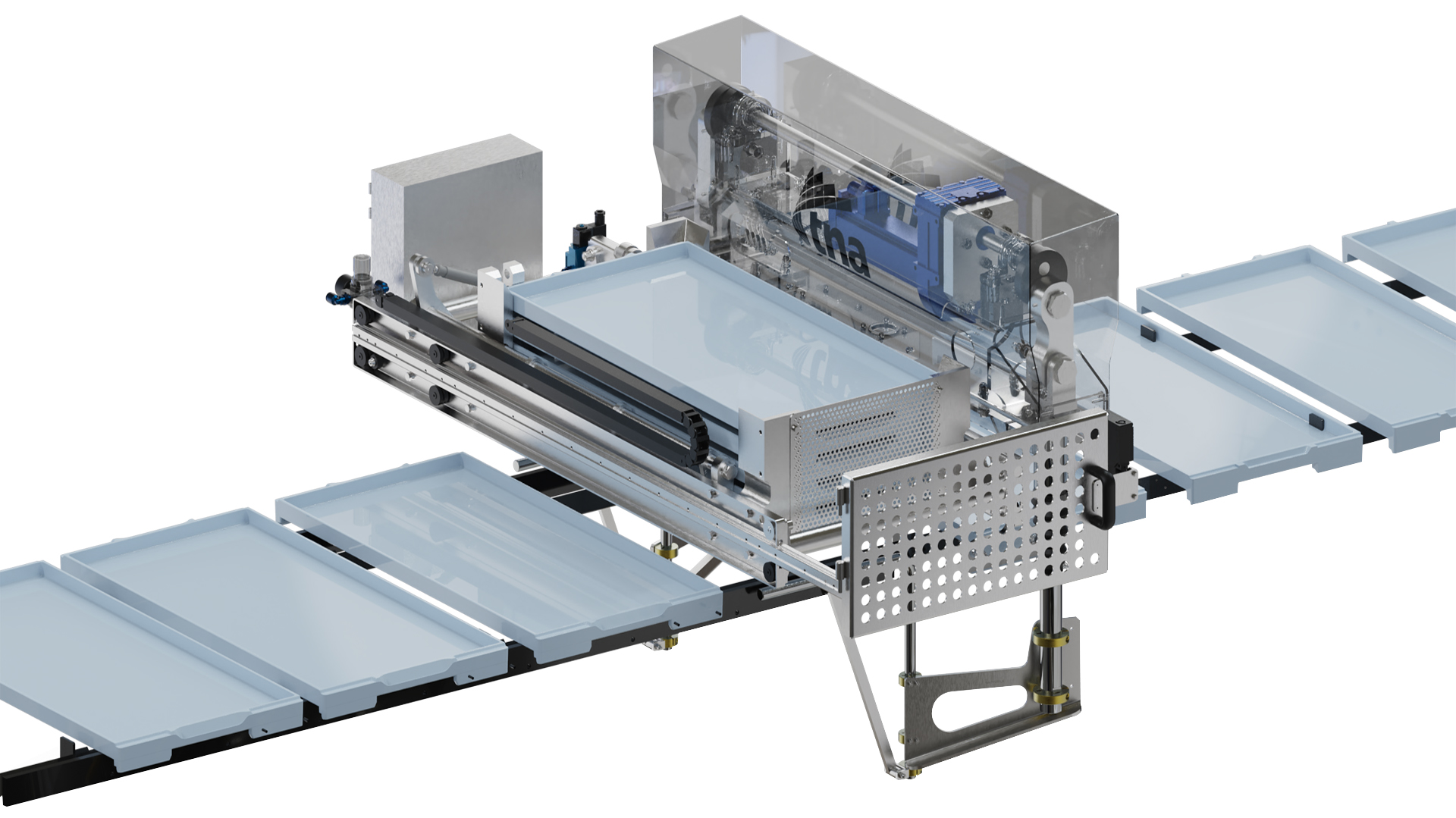

Servo Motors

Servo motors available for these tna mogul components: Printer Table Drive, Tipper Arm Drive, Feeder Main Drive, Stacker Main Drive.

Upgrade outdated mechanisms with tna mogul servo motors, offering superior control, safety, precision, and reliability over traditional mechanical systems. Unlike mechanical motors, servo motors provide greater accuracy, smoother operation, and improved energy efficiency, reducing wear and maintenance while enhancing overall performance.

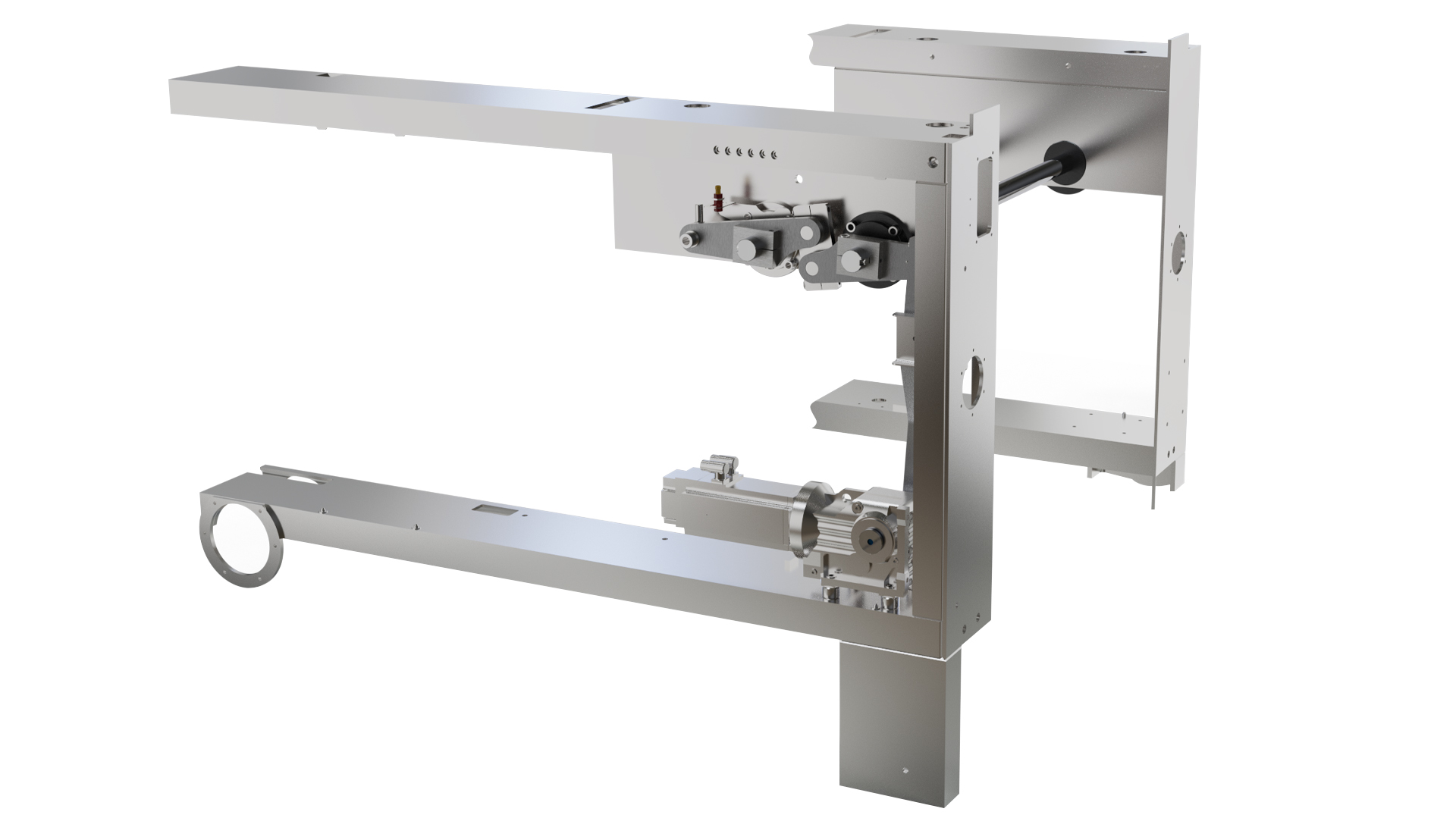

Tray cleaning upgrade

Upgrade your tna mogul with this brushless cleaning system with high-intensity air blowers that efficiently remove starch from tray edges and nesting grooves before the printer table. After printing, the air movers gently clear any spillover without disturbing the mould cavities, ensuring cleaner trays and a more efficient process.

Feeder/Stacker upgrade

Improve your tna mogul feeder and stacker with self-lubricating, oil-filled, food-grade nylon chain box, engineered to reduce wear on surrounding components and eliminate metal-to-metal contact. Includes reinforced heavy-duty clamps that enhance stability for smoother operation, and improved stack straightening to ensure precise alignment. This upgrade brings increased durability and reliability and enhances production while minimising ongoing maintenance.

Other upgrade/retrofit options

- Additional/replacement full tray pump retrofit

- Tray weight check retrofit

- Dirty trays eject retrofit

- Print inspection retrofit

- MCC / PLC electrical upgrades

- Safety upgrades

TNA aftermarket care is built around your success — delivering expert support, rapid response, and premium parts to keep your line running at peak performance, long after installation.