Improve efficiencies, increase yield & reduce product wastage

tna robag® 3e

Boost productivity and operational efficiency with the fastest and most efficient VFFS packaging system on the market. Renowned for unparalleled engineering standards and world-first innovations the tna robag® 3e is capable of 250* bags per minute with over 95% efficiency. Available in a wide range of configurations to suit the needs of your production line.

tna auto-splice 3

The tna auto-splice 3 system# is an innovative solution that automatically joins a new film to an expiring film roll with no interruption to packaging line. Featuring a dual-spindle film system and rotary reel swapping mechanisms, a new pre-prepared film is always ready to take over from the current roll. This helps reduce film waste and removes the downtime associated with manually splicing and replacing rolls, increasing uptime by up to 5%*. The result; a more productive and profitable packaging line, capable of producing up to 2,800 more bags per line, per day*.

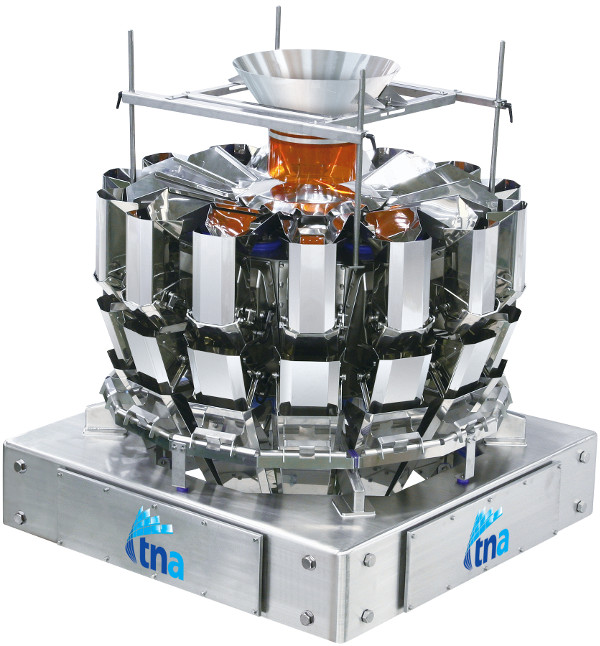

tna intelli-weigh® omega series

Simplify weighing processes for both wet and dry applications with the tna intelli-weigh® omega series. With a stainless-steel construction and waterproof scales, these efficient multi-head weighers offer an advanced hygienic design that goes beyond industry standards to ensure seamless maintenance and quick product changeovers. The series is eco-friendly too, helping to reduce product waste, while its simple structure requires fewer parts that need changing due to wear and tear. In addition, a modular actuator unit provides quick troubleshooting, when needed.

tna intelli-weigh® alpha advance series

The tna intelli-weigh® alpha advance series of multi-head weighers is a simple, affordable weighing solution that does not compromise performance or efficiency. Suitable for dry applications, it features a 10.4″ colour touchscreen for seamless operation, while its streamlined design with fewer moving parts and specially designed radius corner buckets, makes it easy to maintain and clean for faster product changeovers.

tna hyper-detect® 5

Protect your brand’s reputation with the tna hyper-detect® 5. This high-performance food metal detector system is uniquely designed to sit as close as possible to the multi-head weigher, significantly increasing bagging speed without compromising food safety. The tna hyper-detect® 5 is ultra-sensitive, detecting ferrous contaminants from 0.8mm to 0.9mm, non-ferrous pieces down to 1.0mm, and non-magnetic stainless steel from 1.0mm to 1.2mm.

tna intelli-detect® 3

Protect your product from contamination with the tna intelli-detect® 3 – a highly accurate throat metal detector specially designed to detect contaminants of less than 0.5mm in diameter, in addition to any metals. These include including ferrous, non-ferrous and non-magnetic stainless steels (grade 316). In addition, the tna intelli-detect® 3 integrates seamlessly with any VFFS packaging system.

tna intelli-date® 5

The tna intelli-date® 5 is a smart thermal transfer overprint (TTO) date coder, designed to improve uptime and productivity through the reduction of waste and rejects. The system features innovative technology, including an airless all-electronic system, integrated code defect detection and easy-to-change ribbon drive.

tna smartdate® x60

The tna smartdate® x60 is an innovatively designed high performance date coder that applies date codes and/or batch codes accurately and clearly using high-quality print. With high-resolution thermal transfer technology and a unique electronic ribbon drive system, the system prints on moving packaging films, increasing production uptime.

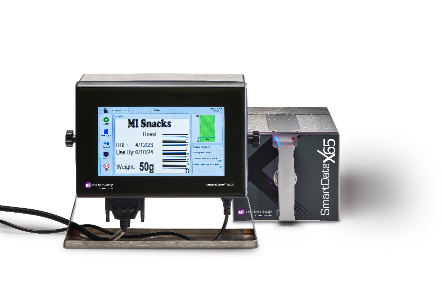

tna smartdate® x65

The tna smartdate® X65 is an advanced high-performance date coder that uses thermal transfer technology and an electronic ribbon drive to print date codes accurately and consistently on flexible film packs. This system is designed to suit even the most demanding, high-volume applications. Capable of delivering up to 455 packs per minute, it is supported by an intuitive 10.1” touch-screen display and features a unique tracking and reporting function to help boost OEE. The tna smartdate® X65 also includes an optional smart-date detect-plus verification system that is ideal for removing faulty codes and safeguarding your brand.

Just 1 operator for 5 packaging lines*

Waste as low as 0.1% for snack foods & confectionery*

Up to 98% packaging efficiencies*

boost productivity and operational efficiency

Experience the following benefits with TNA’s packaging system:

- Built on patented world-first innovations: tna robag® 3e is the world’s most efficient VFFS packaging system delivering industry-leading performance for confectionery and snack packaging.

- continuous rotary motion: TNA patented the world’s first continuous rotary-motion jaw machine which increased industry-standard speeds from under 60 to 120 bags per minute. Today, thanks to continued innovation the tna robag® 3e is capable of 250 bpm*.

- integrated bag maker: TNA was first to market, in 1998, with an integrated bag maker offering single touch HMI control of the connected components – scales, metal detector, date coder and recipes.

- advanced film feed system: This patented straight-through film pass design improves film tension and alignment, further reducing film wastage and increasing output quality. The feed system enables operators to change and thread replacement film in under one minute.

- maximise efficiency and minimise waste: The tna auto-splice 3 automatically joins a new film roll to an expiring roll. This reduces downtime, giving back extra time to operators during their shift so they can focus on high-priority tasks.