tna robag® FX 3e

Built on world-first innovations, tna robag® 3e is the world’s most efficient VFFS packaging system delivering industry-leading performance for confectionery and snack packaging.

Its simplified design with fewer moving parts ensures minimal maintenance and improved energy efficiency. Quick- change parts design enable faster changeovers.

The tna robag® 3e communicates with tna intelli-flav® and tna roflo®. Together, the individual distribution, seasoning and packaging systems form one cohesive and efficient solution that enhances product throughput, reduces waste, and ensures consistent high-quality products.

Unparalleled engineering standards allows speeds of up to 250 bags per minute* with over 95% efficiency.

Simplified mechanical design ensures minimal maintenance, reducing wear and enhancing energy efficiency.

Time saving maintenance and modular design with fast tool-less parts changeovers.

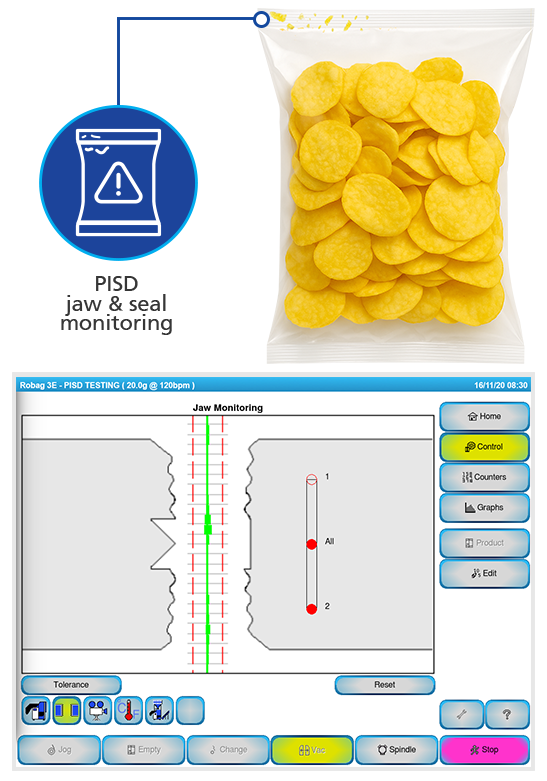

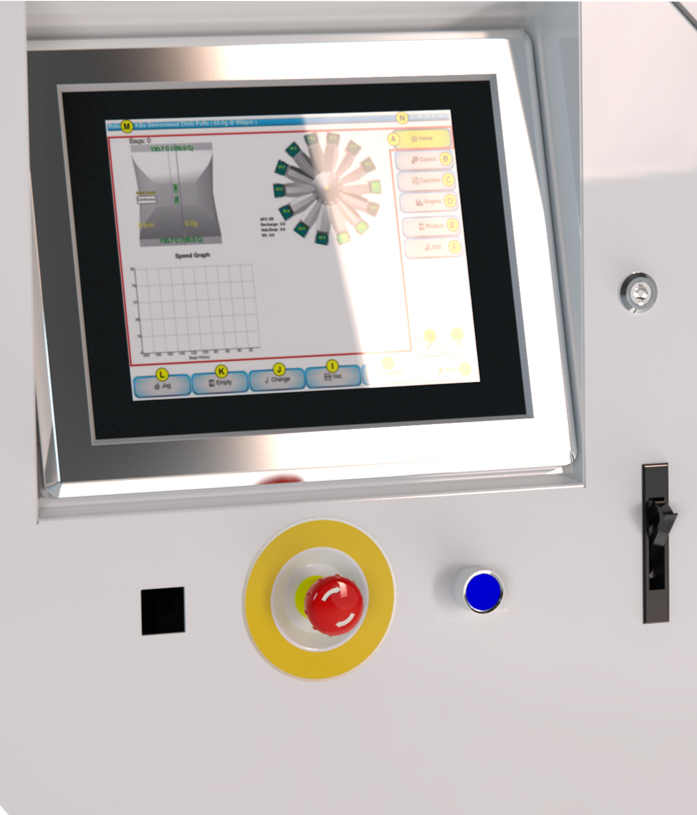

Highest possible build quality paired with smart diagnostics that monitor performance to quickly identify and resolve issues.

The modular tna robag® 3e platform shares components with earlier models, simplifying maintenance and inventory.

When paired with tna auto-splice, line efficiency is boosted to over 98% and productivity by an additional 5%.

The tna robag® 3e communicates with tna intelli-flav® and tna roflo® to form one cohesive and efficient solution that enhances product throughput, reduces waste, and ensures consistent high-quality products.

*speeds determined by bag size, film and product type.

- High-speed continuous motion rotatory jaw system

- Central HMI control of bagmaker and connected accessories

- Single pass film feed, complete changeovers in under 1 minute

- Former unload assist fast tool-less former system

- Few moving parts, reducing maintenance/energy usage

- Bag sizes: 40mm – 420mm width

- Bag types: pillow, serrated, string, block bottom, quattro etc

- Modular, tool-less design for quick parts changeover

- Equipment integration: tna robag® 3e can be integrated with tna intelli-flav® and tna roflo® creating a unified intelligent system

- Rotary jaw options

- single | 100 bpm*

- double | 150 bpm*

- triple | 250 bpm*

- flat | 75 – 125 bpm*

*bags per minute speeds (bpm) determined by bag size, film and product type.

Options

- Modular design with flexible integration options:

- tna intelli-weigh® multihead weighers

- tna hyper-detect® metal detectors

- tna intelli-date® code applicator

- tna intelli-read® barcode verification

- bag collators

- inserters

- programmable string bag systems

- tna take away conveyors

- check weighers

- Product–in-seal detection (PISD) regulating software

- Modbus/TCP connectivity for system and device integration

- Date coder path length adjustment

- tna auto-splice continuous film feeding system boosts efficiency to over 98%

| tna robag® FX 3e | rotary triple jaw | rotary double jaw | rotary single jaw | rotary flat jaw | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 180 | 180 | 230 | 320 | 180 | 230 | 320 | 230 | 320 | 420 | ||||

| performance | max running speed bpm | 250 | 200 | 200 | 200 | 100 | 100 | 100 | 125 | 125 | 75 | ||

| utilities | average air consumption @6bar (87psi) L/min (cfm) | 3 (0.11) | 6 (0.22) | ||||||||||

| controller | CXE | ||||||||||||

| power consumption kW (hp) | 4.2 (5.6) | 3.5 (4.7) | 2.8 (3.8) | 3.5 (4.7) | |||||||||

| voltage | 3PH 208~480VAC | ||||||||||||

| specifications | bag length | minimum mm (in) | 50 (2) | ||||||||||

| maximum mm (in) | 180 (7.1)** | 1000 (39.4) | |||||||||||

| bag width | minimum mm (in) | 40 (1.6) | |||||||||||

| maximum mm (in) | 180 (7.1) | 180 (7.1) | 230 (9.1) | 320 (12.6) | 180 (7.1) | 230 (9.1) | 320 (12.6) | 230 (9.1) | 320 (12.6) | 420 (16.5) | |||

| film roll | maximum width mm (in) | 384 (15.1) | 384 (15.1) | 484 (19.1) | 664 (26.1) | 384 (15.1) | 484 (19.1) | 664 (26.1) | 484 (19.1) | 664 (26.1) | 1000 (39.4) | ||

| diameter mm (in) | 400 (15.7) | ||||||||||||

| maximum weight kg (lbs) | 50 (110.2)* | 150 (330.7) | |||||||||||

| construction material | powder coated mild steel or stainless steel | ||||||||||||

| tunnel guard opening mm (in) | 610 (24) | ||||||||||||

| height mm (in) | lowlander | total | 1800 (70.9) | 2360 (92.9) | |||||||||

| former | 1760 (69.3) | 2360 (92.9) | |||||||||||

| midlander | total | 1800 (70.9) | 2360 (92.9) | ||||||||||

| former | 1835 (72.2) | 2360 (92.9) | |||||||||||

| highlander | total | 1800 (70.9) | 2360 (92.9) | ||||||||||

| former | 1910 (75.2) | 2360 (92.9) | |||||||||||

| jaw height mm (in) | lowlander | 680 (26.8) | 830 (32.7) | ||||||||||

| midlander | 680 (26.8) | 830 (32.7) | |||||||||||

| highlander | 830 (32.7) | ||||||||||||

| depth mm (in) | 1910 (75.2) | 3200 (126) | |||||||||||

| width mm (in) | 900 (35.4) | 1700 (66.9) | |||||||||||

| weight kg (lbs) | 1000 (2204.6) | 1500 (59.1) | |||||||||||

| all above specifications are subject to change and may differ according to product, please confirm when placing your order. * 35kg is recommended to minimise film tracking variations. ** bag length is indicative and requires testing. |

|||||||||||||

Collaterals

Case Studies

- Majans: Enhanced uptime and 140% throughput increase with fully automated packaging system.

- Burton’s Biscuits: Leading biscuit manufacturer double packaging speeds and assure quality.

- Burts: TNA helps premium snack manufacturer boost production capacity

- Future Foods: Egyptian snack manufacturer, drive continued innovation

- Kingsway Confectionery: Accelerated growth through increased production capacity and expert support

- Mister Bee: Optimised manufacturing facility increases output by 400%

- Riverside Foods: Organic snack producer doubles packaging speeds with integrated solution

- Whitby Seafoods: Frozen seafood manufacturer doubles packaging speeds

- Pipers Crisps: Increased outputs from 80 to 140 bags per minute with a 66% reduction in waste

- Keystone: 30% boost to productivity with impressive waste reduction