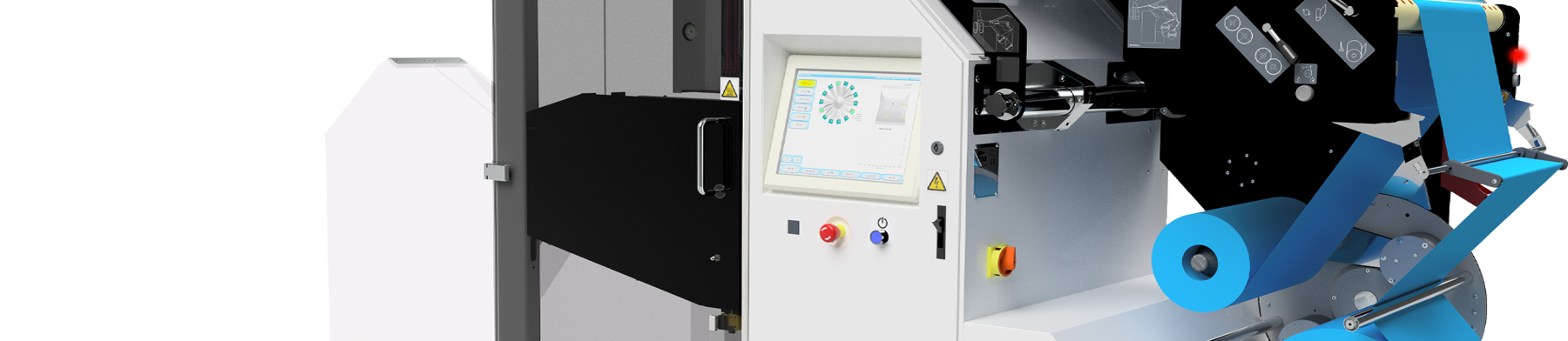

tna auto-splice 3

The tna auto-splice 3 enables continuous film feeding thanks to its patented design with advanced splicing and auto-rotating dual film roll functionality. This drastically increases bag-making capacity by reducing the downtime associated with the conventional single spindle setup. This not only enhances production capacity, but it also optimises operator efficiency by freeing up time to focus on high-priority tasks.

The fit-for-purpose design fits snugly onto the tna robag® 3, adding just 200 mm to the overall length making it the most compact integrated auto-splice solution on the market

Intelligent multi-function auto-tracker ensures the film roll maintains the correct alignment for optimal uptime.

Enhances production capacity while optimising operator efficiency by freeing up their time to focus on high-priority tasks.

Integrates with the tna robag® 3, extending its overall footprint by only 200m and enhances its high-speed and line efficiency capabilities, reducing waste down to 0.1%.

Innovative vacuum positioning system allows the operator to quickly secure the new film in place, ensuring precise and efficient joining to the expiring roll.

- retrofittable to tna robag 3ci machines

- compact design, adds only 200mm to robag footprint

- excellent accessibility to splice preparation area

- simple operator film preparation

- unique film reel swapping

- max reel diameter 350mm

- max FBW of 310mm (220mm on robag 230 machine)

- ability to complete registered splice

- includes film auto-tracking as standard

| tna auto-splice 3 automatic film splicing system | ||

|---|---|---|

| reel width | 230mm jaws | 320mm jaws |

| maximum 482mm (18.98inch) | maximum 632mm (24.88inch) | |

| reel diameter | maximum 350mm (13.78inch) | |

| tape specification | standard packing tape – polypropylene or polyster, 40-50mm (1.52inch) wide recommended | |

| power consumption kW (hp) | less than 100Watts | |

- Dal

- Gummies & jellies

- Other Snacks

- Pellets - dry

- Pork rinds

- Potato chips

- Tortilla chips

- Packaging systems