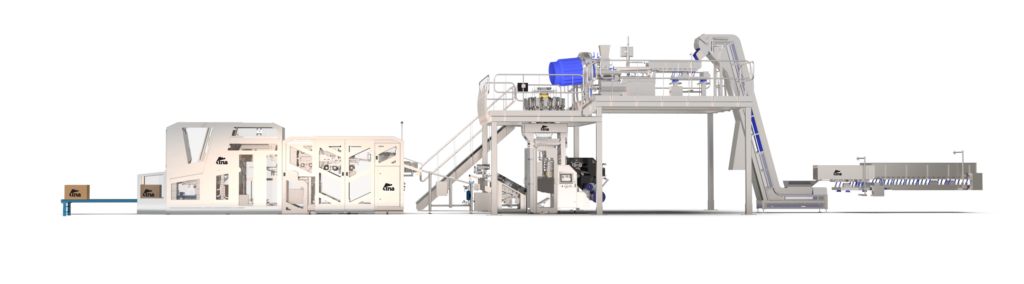

Discover our advanced solutions:

tna roflo® HM 3

Our tna roflo® VM 3 is a conveyor system that uses vibratory motion technology to quickly and evenly distribute products without compromising on handling. Its patented design offers in-line storage and a variety of pan options to suit even the most niche production needs.

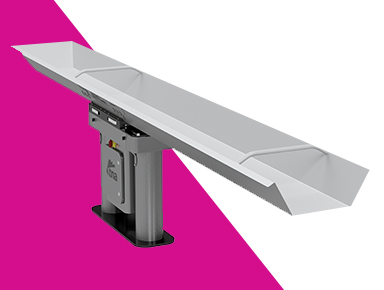

tna roflo® VM 3

Our tna roflo® VM 3 is a conveyor system that uses vibratory motion technology to quickly and evenly distribute products without compromising on handling. Its patented design offers in-line storage and a variety of pan options to suit even the most niche production needs.

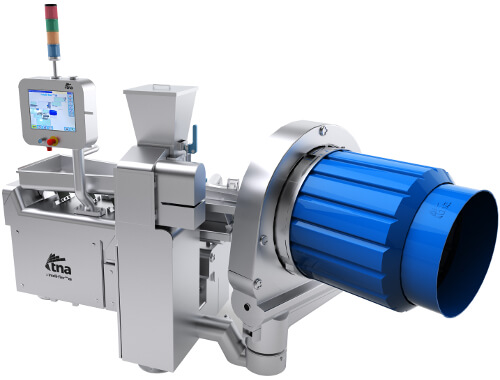

tna intelli-flav® OMS 5.1

The tna intelli-flav® OMS 5.1 is a next-generation on-machine seasoning (OMS) system that provides both powder flavouring and liquid oil in a single drum, to deliver consistent coverage and flavour to a variety of products. Designed to IP65 standards, it meets even the highest hygiene and sanitation requirements.

An update of the tna intelli-flav® OMS 5, the tna intelli-flav® OMS 5.1 offers a range of host features, including an optional high-capacity stainless-steel drum and integrated heated oil circulation system. These options enable the accurate seasoning of an even wider range of hot or cold products, such as fried, baked and puffed snacks. In addition, the system can handle confectionery, including gummies, and frozen food applications that require more rigorous sanitation procedures.

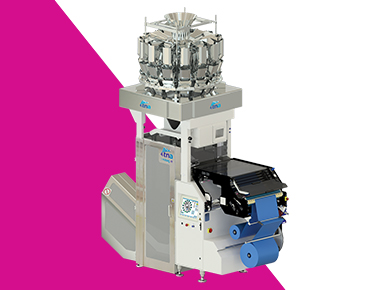

tna intelli-flav® MLS 3

The tna intelli-flav® MLS 3 is a high-performance, gravimetrically controlled main-line seasoning (MLS) system that pairs with the tna intelli-flav® CLO 3 or tna intelli-flav® CLS 3 to disperse dry and wet flavourings with extreme accuracy – for consistent application with minimal waste and product damage. Featuring modular components, the system can be upgraded in line with business growth, to meet production demands and protect your investment.

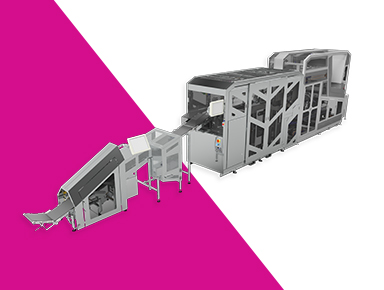

tna robag®FX 3e

tna robag®FX 3e is a high-performance vertical form fill and seal (VFFS) packaging system that delivers the fastest speeds in the industry and the latest in automation with real-time EtherCAT® protocol.

Reaching up to 250 bags per minute*, the tna robag®FX 3e also offers superior flexibility thanks to its rotary triple, double, single and flat jaw configurations. With an integrated display controller CXE, smart diagnostics system, and enhanced serviceability, the tna robag®FX 3e bags just about any type of snack (or food application) faster and more efficiently than anyone else.

tna auto-splice 3

The tna auto-splice 3 system is an innovative solution that automatically joins a new film to an expiring film roll with no interruption to packaging line. Featuring a dual-spindle film system and rotary reel swapping mechanisms, a new pre-prepared film is always ready to take over from the current roll. This helps reduce film waste and removes the downtime associated with manually splicing and replacing rolls, increasing uptime by up to 5%*. The result; a more productive and profitable packaging line, capable of producing up to 2,800 more bags per line, per day*

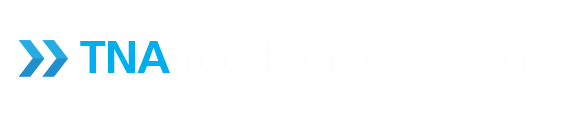

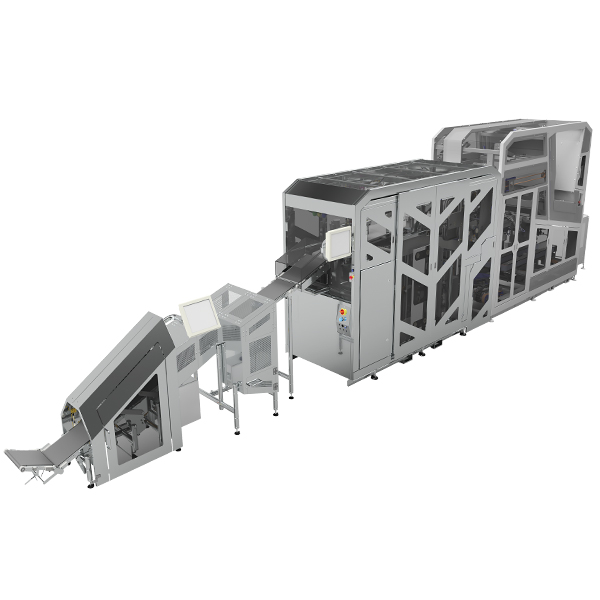

tna ropac® 5

The world’s fastest case-packing system for flexible bags capable of packing up to 200 bags per minute. Using TNA’s own patented semi-rotary technology, the tna ropac® 5 case packer is designed to pack small-to-medium, pillow style snack bags. Most bag widths and lengths are handled with ease for packing various applications such as snacks, confectionery, pasta and cereal.

Benefits to your production line

- Optimal throughput

- Increased efficiencies

- Reduced cost of ownership

- Reduced maintenance costs

- Single point of dedicated aftermarket care

- More uptime