All You Need To Know About Industrial Noise Control

posted on 24 March, 2020 by Tim Scott

Noise is an inevitable by-product of almost any manufacturing or packaging process — regardless of the industry. Although eliminating industrial noise is nearly impossible, operators must take careful measures to control it, to comply with health and safety regulations and protect workers’ health and well-being.

Here, we discuss the importance of minimising noise pollution in food processing and packaging factories, as well as how to assess and manage risk.

Industrial noise: why should I care?

In industrial settings, high decibel levels of noise are considered a health and safety hazard and can lead to various irreversible consequences:

- In humans, it can cause temporary or permanent conditions, such as hearing loss or tinnitus-ringing in the ears. In fact, industrial hearing loss — although preventable — remains the occupational disease with the highest number of civil claims (75%) in the UK.[1] In Australia, there were 65,300 accepted claims for deafness between 2001 and 2015, with over a third (35%) of these claims made by staff in the manufacturing industry.[2]

- Exposure to industrial noise above health and safety standards can affect the mental health of workers, with stress and hypertension common in employees working in loud environments.

- It can be detrimental to the surrounding eco-system, affecting wildlife by interfering with its communication and navigation.

Limiting industrial noise to the recommended levels promotes a sustainable environment that safeguards both the health and wellbeing of individuals and wildlife.

Assessing risk level

If a source or process that may expose workers to hazardous noise has been identified, a noise exposure measurement in consultation with affected staff should be carried out. Most global health and safety regulations state that noise levels should not exceed 85 A-weighted decibels [dB(A)]. Although ideally, they should be limited to 50 dB(A) for work that requires high concentration and 70 dB(A) for routine tasks.

The quickest way to assess noise levels in the workplace is the ‘one metre rule’. If one must raise their voice to have a conversation with another person one metre away, it can be assumed that the sound level is hazardous. Meanwhile, the most common instruments to measure industrial noise are the sound level meter (SLM), the integrated sound level meter (ISLM) and the noise dosimeter.

What measures can be taken?

Supervisors should carry out regular inspections to detect damaging noise levels and take immediate action to control them. There are several measures that can be taken to limit the impact of unsafe industrial noise. This includes ear protection for staff, plugging electrical equipment into the main power supply to eliminate the need for loud generators or moving machines, as far away from staff as possible, via extension cords. The most effective approach to ensure health and safety regulations are upheld in the long term, however, is replacing machinery that produces dangerous levels of noise with the latest technology able to perform at or below noise exposure standards.

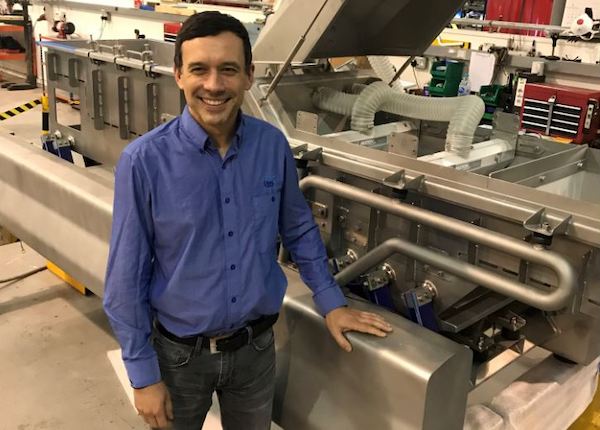

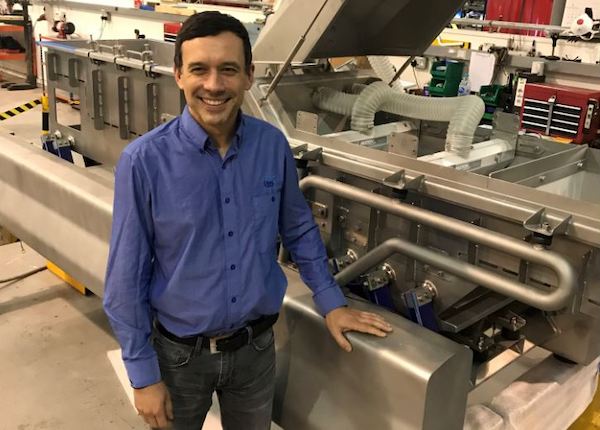

In the spotlight: conveying systems

High in demand in the food processing industry due to its ability to handle multiple products on a single line, conveying equipment can be found in most production plants worldwide. This type of equipment traditionally produces hazardous noise levels. Although, the latest conveying technology on the market ensures that noise exposure standards are met — protecting staff and providing peace of mind for operators.

The tna roflo® VM 3, tna roflo® VMCS 3 and tna roflo® HM 3, for example, are tuned and extensively tested to meet health and safety standards globally, running at 70 dB(A) sound pressure level, one metre from the machine. They comprise a stainless-steel construction with a powerful single drive operation and gentle vibratory and horizontal movement. tna experts continually monitor the performance of these systems to ensure they are compliant, as well as make improvements wherever possible.

The next step

The right partner can support operators in both assessing the risk of industrial noise and implementing an effective strategy to control it. To know more, connect with us at: [email protected]

[1] Health and Safety Executive, Noise induced hearing loss, https://www.hse.gov.uk/food/noise.htm [2] Safe Work Australia, Noise, https://www.safeworkaustralia.gov.au/noise

Español

Español  Português

Português  Italiano

Italiano  日本語

日本語  中文

中文  Français

Français  Deutsch

Deutsch  Русский

Русский  العربية

العربية