As the world’s leading provider of food processing solutions, we can offer you unmatched expertise and the most complete range of solutions in the industry, complemented with superior customer service. This powerful combination of advanced technologies and on-ground proficiencies enables you to meet your goals in a supportive partnership – from conception of a project to consultation, completion and beyond.

We are the food processing solutions partner of choice for today’s leading businesses.

Our innovative food processing solutions help food manufacturers globally to deliver the quality food experiences customers continue to demand.

tna conti-pro® FF 3

Made to handle french fries applications. Built using zonal flow oil injection technology, the tna conti-pro FF 3 food processing solution delivers oil optimisation and consistent product textures.

tna conti-pro® PEL 3

Designed with a four-belt processing system to handle a wide range of pellets and product shapes. Its four-belt design ensures even oil applications and consistent product quality.

tna vac-pro® 3

Its continuous vacuum frying system reduces oil absorption and minimises acrylamide formation, delivering fried food products with a healthier fat content.

tna batch-pro® 12

Uses a serpentine heat exchanger tube configuration to enable batch-frying processes across a number of chip applications, including potato, taro, plantain and banana.

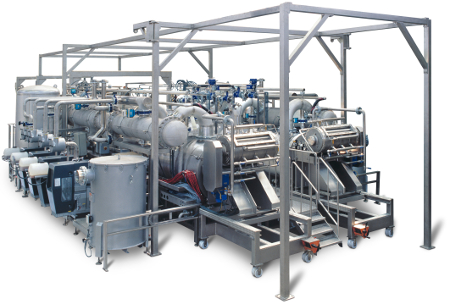

tna conti-pro® PC 3

A high-performance continuous frying system designed specifically for potato chips. Equipped with our patented opti-flow technology, this food processing machinery enables the production of a dynamic range of potato chip products.

tna accura-dry® BD 3

Removes excess moisture from french fries products prior to frying for a more consistent texture, reducing heating times during this phase for enhanced production capacity.

tna cryo-jet 5

Trusted by leading global brands, this ambient air-cooling system is engineered to rapidly cool baked and fried products before freezing or packaging. Using high-velocity air impingement technology, it dissipates excess heat up to 10 times faster than conventional fan-forced cooling methods.

tna ultra-peel® SKC 3

Uses advanced weighing technology and an abrasive peeling system to deliver peeling precision and high product retention rates.

tna ultra-peel® SSC 3

A stainless steel steam peeler with highly efficient internal systems designed to reduce maintenance costs and food material wastage.