Innovations Update: tna roflo VM 3 conveyor blending system

products | 2 mins read

April 6, 2016

In an effort to continually support our customers, we always strive to provide greater operational efficiency and improved performance. Our most recent innovation update is the new tna roflo® VM 3 conveyor blending system.

In an effort to continually support our customers, we always strive to provide greater operational efficiency and improved performance. Our most recent innovation update is the new tna roflo® VM 3 conveyor blending system.

Challenge

Typically, multi-head bucket weighers are used to blend two or more dry/pellet-type products that require accurate proportioning. The desired percentage of the mix would be divided between the number of heads. However, throughput is limited by the number of heads available, and such a system can be expensive to set up and maintain.

Solutions

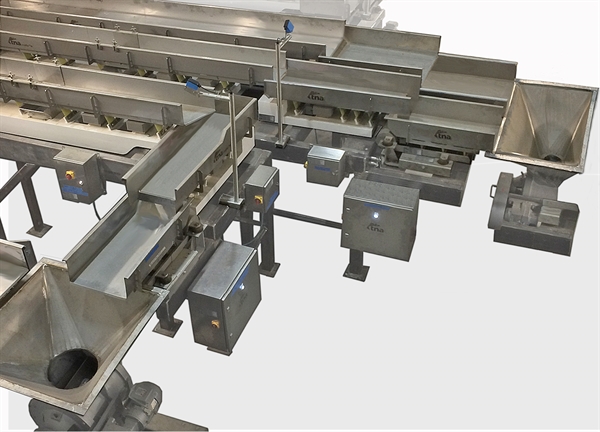

tna engineers integrated tna roflo® VM 3 conveyors with built-in weigher platforms to create an accurate and efficient dry product blending system.

The new solution uses tna’s seamless system integration and control software, as well as their human machine interface (HMI) and supervisory control technology to manage product blending. It employs a twin lane configuration and uses weigher information to give the packaging machine an accurate and continuously blended product feed. The product weight is accurately measured in each lane, and the flow rate is controlled to mix the products at the required proportions. The tna blending system eliminates the need for separate and expensive weigher/mixing systems, speeding up the production throughput.

Benefits

The new tna roflo® VM 3 conveyor blending system provides several key benefits:

- production flexibility, with different variations at the touch of a button

- ability to perform small-volume runs

- faster production throughput

- cost savings with accurate product blending process

- installation flexibility to allow for two or more dry products

- improved production performance with in-line integration