More than just a date: the latest date coding technology for snacks

products | 4 mins read

December 10, 2018

The global snack food market is growing at an incredible pace. According to market researchers GlobalData, the savoury snacks sector was valued at US$105.7 billion in 2017 and is forecast to record a CAGR of 6.1% during 2017–2022 to reach US$142 billion by 2022. Flexible packaging is still the most commonly used package material in the savory snacks sector due to its excellent barrier properties, cost-effective production and consumer convenience, accounting for 95.7% of the volume share in 2017. Whatever the snack, each bag of treats requires unique product identification information – whether it’s for consumer, traceability or marketing purposes. Dates codes might be a simple communication tool, but there’s a lot more to them than meets the eye. Besides indicating the expiry date, these codes also often contain details about batch number, factory number, line number, operator number and other vital production information. In addition, variable ingredients and nutrition information panels can be printed on demand with the same printer

High-speed dating

The growth and popularity of flexible packaging means that code printing requirements have evolved significantly of the past few years. The growing consumer appetite for small, single-serve snack bags has pushed manufacturing lines to higher speeds in an effort to increase throughput. Achieving clear codes at these high speeds can at times be an issue as not all printers are able to perform at these levels, resulting in an increased number of rejected bags. In addition, higher throughput levels require more frequent ribbon changes, which causes additional downtime. The latest coding technologies are addressing these challenges by supporting manufacturers with advanced printing technology that is able to keep up with higher line speeds.

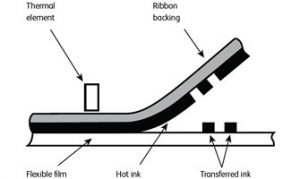

One of the most popular solutions for flexible bags are Thermal Transfer Overprinters (TTOs). These printers have been specifically engineered to work on flexible substrates and are able to overcome many of the deficiencies of analogue printing methods such as hot stamp or roller coders, for example. TTOs apply a code to a flexible film or label by using a thermal printhead and a thermal ribbon. They are a simple and cost-effective way to get high-quality, crisp prints onto flexible film, even at high speeds.

Traditionally, most TTO systems are controlled pneumatically i.e. the printhead is controlled by pressured air. While they are a cost-effective solution, the reality is that they can be quite a time-consuming affair. First of all, operators have to ensure that the air is connected at all times and that the pressure is maintained at the right level in order to ensure a continuous, high-quality print. Any bags without a code or a faded code will be rejected, which not only results in unnecessary waste, but also disrupts the production process and therefore directly affects line efficiency and throughput.

The future is airless

To overcome these issues, the industry is increasingly moving towards airless printing. Controlled electronically, airless TTO systems completely remove the need for compressed air. As such, they are much easier to operate and maintain as there is no need to regularly check the air pressure. In addition, the ribbon lengths of airless of airless TTO’s can be up to 1,200m long and ribbon tension and movement are controlled digitally to ensure the amount of unused ribbon is kept to a minimum. This not only reduces product waste, but also increases up-time, resulting in a significant improvement in production line efficiencies.

Are you ready to take the next step in date coding? Contact us now to find out how our new tna intelli-date 5 airless date coder can increase your throughput by up to 25%.

[1] Opportunities in the Global Savory Snacks Sector, GlobalData (August 2018)