Worth the weight: How to maximise ROI in snack production with effective weighing equipment

June 16, 2020

From between-meal pick-me-ups to post-workout treats, snacks are a staple in many people’s diets. In the US, for example, more than half of consumers are saying they snack every day.[1] Meanwhile, annual spending on snacks in the UK has increased by almost £25 million over the past decade.[2] To meet growing consumer demand while upholding operational profitability, manufacturers are seeking innovative ways to increase product output, reduce waste and lower operating costs.

From between-meal pick-me-ups to post-workout treats, snacks are a staple in many people’s diets. In the US, for example, more than half of consumers are saying they snack every day.[1] Meanwhile, annual spending on snacks in the UK has increased by almost £25 million over the past decade.[2] To meet growing consumer demand while upholding operational profitability, manufacturers are seeking innovative ways to increase product output, reduce waste and lower operating costs.

Responsible for ensuring packs are neither underweight, nor overweight, accurate weighing equipment is one of the most important elements in the snack production line and can allow producers to meet varying needs. By ensuring the right amount of product is bagged, manufacturers can maintain brand consistency, comply with legal requirements and avoid unnecessary waste, all of which – if not achieved – could chip away at profit margins. These fundamental functions are vital to safeguard a brand’s reputation and continue working economically, but effective use of weighing technology can offer so much more than just accurate package filling.

Here, we discuss 5 ways weighing equipment can help manufacturers maximise return on investment (ROI):

-

Reducing product damage

Particularly when working with fragile products like potato chips or dry pasta, some level of breakage is inevitable during the packaging process. To maximise ROI, however, product damage should be kept to a minimum. The good news is that by choosing the right weighing equipment, producers can drastically limit giveaway, minimise breakage and maximise high-quality product output. Shallow radial feeders, gently angled hoppers with curved edges and ring shutters installed in discharge chutes can all assist with lowering drop distances, reducing collisions and generally preventing costly snaps and splits.

-

Ensuring product quality

While some foods might not fully break during the weighing process, surface imperfections, lost coatings and patchy seasoning can still diminish the quality of the end-product. Unchecked rolling and sliding of foods as they enter feeders or hoppers can lead to damaged edges of goods such as biscuits, while unsightly pressure or friction marks can appear on chocolate-covered products like dried fruits or jellies. Specialist materials, such as flexible coatings or liners, applied to all product-touching areas of weighing equipment can help regulate product flow and absorb momentum. This reduces dents and scrapes to maximise high-quality product output and enhance the consumer experience.

-

Faster packaging times

In the food processing and packaging industry, time is money. Fast, precise weighing can support brands in fulfilling rising production quotas and ultimately capitalise on growing demand for snack products. The fastest, most efficient weighing solutions on the market typically feature lightweight, rigid buckets and load cells, which run at a high natural frequency. This helps to reduce weighing response times and lessen the impact of vibration on goods, while still moving products through the system at a rapid pace. These systems can also address concerns around ensuring a steady product feed. Weighing technology, which uses amplitude detectors on the feedline, can automatically detect and feedback the precise level of vibration needed for efficient product feeding. This auto-tuning, when used in conjunction with Auto Feed Control (AFC), delivers a system with optimal product volume and feedline speed for the best possible performance.

-

Flexibility and New Product Development

Highly accurate weighing solutions allow manufacturers to develop new or refine already-marketed products by precisely weighing combinations of different component foods to create exciting, on-trend snack mixes of cereals, gummies, frozen fruit and much more. For instance, a multi-head weigher can be programmed to produce 400g bags of trail mix, each comprised of four separate ingredients. Using intelligent software, the weigher can calculate the proportion of each ingredient, automatically adjusting the ratio between ingredients to confirm the final product matches the target weight. This is particularly important when processing premium snack mixes, as every gram of more expensive ingredients counts. Advanced weighing equipment not only helps producers keep up with ever-changing market trends, but also ensures this agility can be achieved without significant risk to profit margins.

-

Reliability and longevity

The best weighing solutions don’t just offer quality, speed and accuracy, but consistent, long-lasting performance with minimal downtime. Selecting the best-suited, high-quality equipment from an expert supplier is the first step to making sure weighing equipment can stand the test of time. To ensure solutions live up to their full potential, however, producers must introduce effective maintenance practices. This can help to avoid the high costs associated with major repairs – making this perhaps the simplest way to maximise ROI. Replacing filters regularly, for example, ensures dirt does not build up and restrict the flow of cooling air needed to prevent electronic components within the weigher from overheating. The filters used in dosing weighers used for ‘waterproof’ applications like frozen or fresh produce, not only collect dust, but also remove moisture from the equipment’s interior. If these filters become blocked, condensation can accumulate inside the weigher with serious consequences: inaccurate results, damage to the I/O-boards, rust, defective actuator units and even short-circuiting. It is therefore vital that filters are replaced twice each year in these applications.

Weighing up the options: choosing the right weighing solution for your application

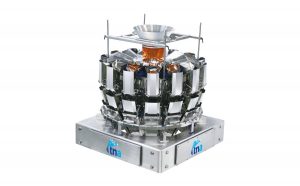

Weighing solutions which offer the best ROI are those that balance gentleness and speed, with accuracy and reliability. Built on these industry needs, tna’s complete portfolio of high-quality, flexible weighing equipment is tailored to suit any application and budget. Our premium tna intelli-weigh® omega series of multi-head weighers offers unparalleled performance and control, increasing weighing speeds by up to 30%, while the self-adjusting feed pans and auto-tune function provide stable feeding and improved accuracy. Weighing parameters can also be modified at any point throughout operation, helping to reduce downtime and enable a faster product turnaround. With each component specially designed for easy cleaning and fewer moving parts, the tna intelli-weigh® omega series exceeds industry standards for hygiene and economic efficiency, while delivering the best possible value for money.

Find out more about the tna intelli-weigh® omega series, and our other industry leading weighing solutions, here. http://www.tnasolutions.com/solutions/weighing-solutions/

[1] The International Food Information Council (IFIC) Foundation, 2019 Food and Health Survey, https://foodinsight.org/wp-content/uploads/2019/05/IFIC-Foundation-2019-Food-and-Health-Report-FINAL.pdf

[2] Consumer spending on food in the United Kingdom from 2005 to 2018, Nov 14, 2019, https://www.statista.com/statistics/289911/expenditure-on-food-in-the-united-kingdom-uk/