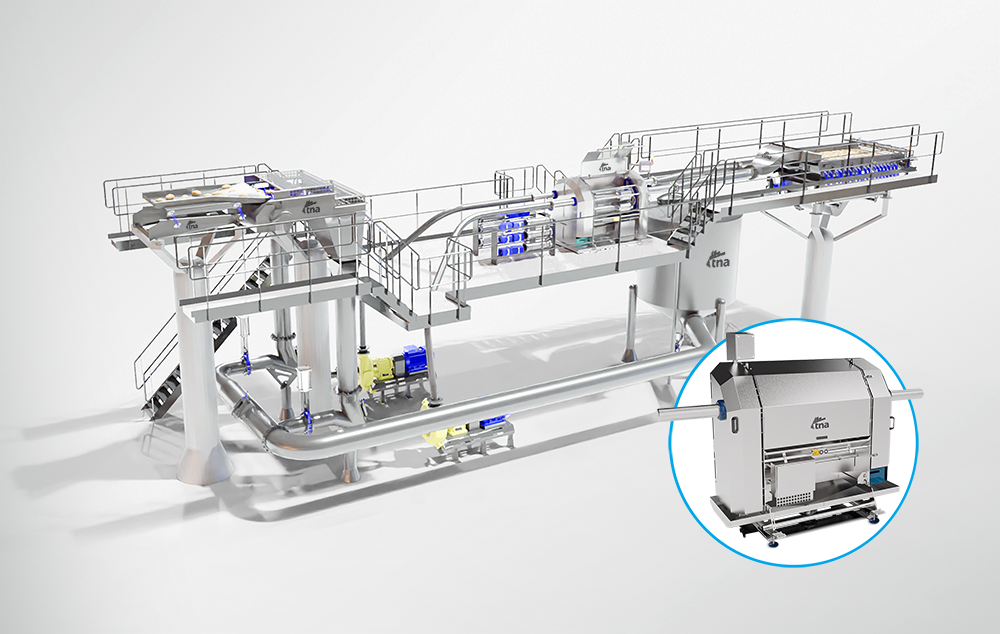

tna conti-cut

tna conti-cut hydro cutting system is the new, cutting-edge solution in french fries processing. Universally compatible with all potato processing lines, regardless of geographical location, the integral ‘switcher’ alignment tube and knife block enables the tna conti-cut to easily deliver against the industry’s highest output capacity (approx. 30Mt/hr) – driving efficiency, consistency and productivity.

Drive efficiency, productivity, reduce waste and maximise uptime

Minimum downtime to replace wear parts

Available for french fries processing lines of all potato sizes regardless of geo location and throughput requirements

Ease of access to suction header in event of clogs or blockages, maximising uptime in the event of potential blockages

Achieve the longest cut size possible when processing potatoes in high volume through the alignment tubes

Add flexibility with an interchangeable knife block, enabling potatoes to be cut into different shapes and sizes, such as: sticks, wedges, and slices

- Pressure transmitter

- Switcher housing a revolver, with 2 alignment tubes and 2 knife blocks

- Integrated drain/waste area at bottom of the switcher

- The switcher is integrable in existing lines thanks to stand-alone controls

- Knife blocks are available in different potato diameters and cutting shapes

- Flow valvle

- For cost-saving criteria, a static setup (without switcher) for French fries lines is available, enabling clean cut product that cannot be achieved when using a mechanical cutter(no serrated surface structure).

| tna conti-cut | ||

|---|---|---|

| model name | tna conti-cut | |

| max throughput (ton/hr) | Ca. 12 ton/hr* | |

| alignment tubes are available for | Wedges Ø50, fries Ø85 & Ø110 | |

| switcher dimensions | length m (in) | 1.8 m (70.87′) |

| width m (in) | 1.0 m (39.37’) | |

| height m (in) | 1.65 m (64.96’) | |

| Installed electrical power kw | Ca. 22 kw pump drive | |

| Compressed air consumption | Ca. 25 Nltr./hr | |

| * All above specifications are subject to change and may differ according to product, please confirm when placing your order. ** Best results are achieved when potatoes are pre-graded and potato size are aligned by the proper alignment tube. |

||

- French fries

- Potato Slices

- Potato Wedges

- Processing solutions