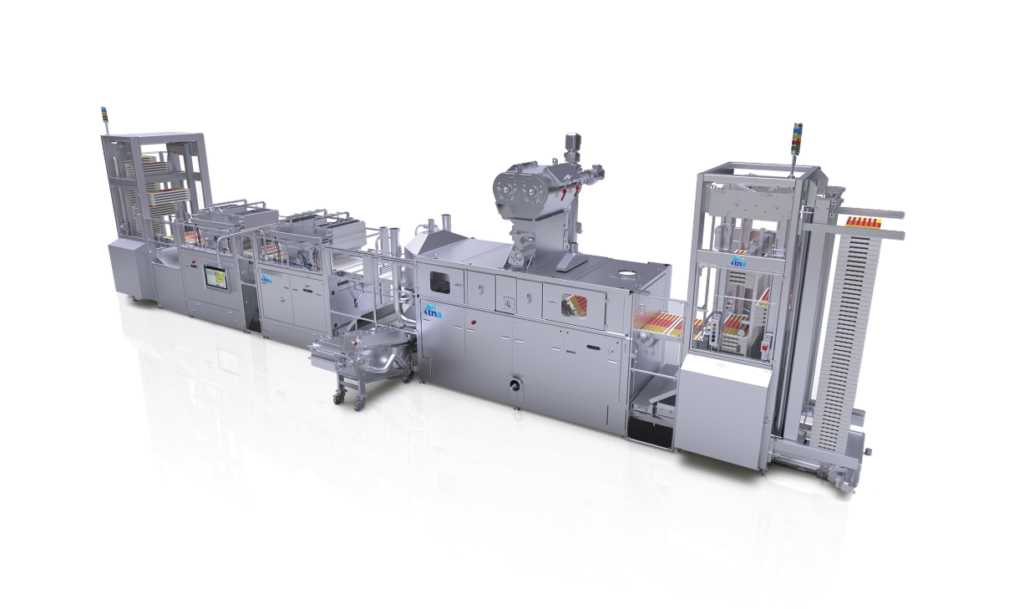

The tna mogul® redefines what’s possible in gummy manufacturing. From complex shapes to custom textures and nutraceutical formulations, it delivers unmatched flexibility—without sacrificing speed or control. Backed by industry-leading equipment and expert support, this all-in-one line streamlines gummy production with intelligent, recipe-driven automation. One operator. Minimal footprint. Maximum output. Designed to scale with your ambition.

create consistent moulded confectionery items

The latest in starch moulding technology, the tna mogul ST is designed to efficiently and consistently mould a large range of confectionery items, including gummies, jellies, marshmallows, fondant cremes, centre-in-shell, nutraceuticals and liquorice.

This solution is a complete, all-in-one moulding product (equipped with fully integrated feeder, starch buck, depositor, stacker and pallet transport system). With this technological profile, the tna mogul ST empowers you to produce consistently high-quality products.

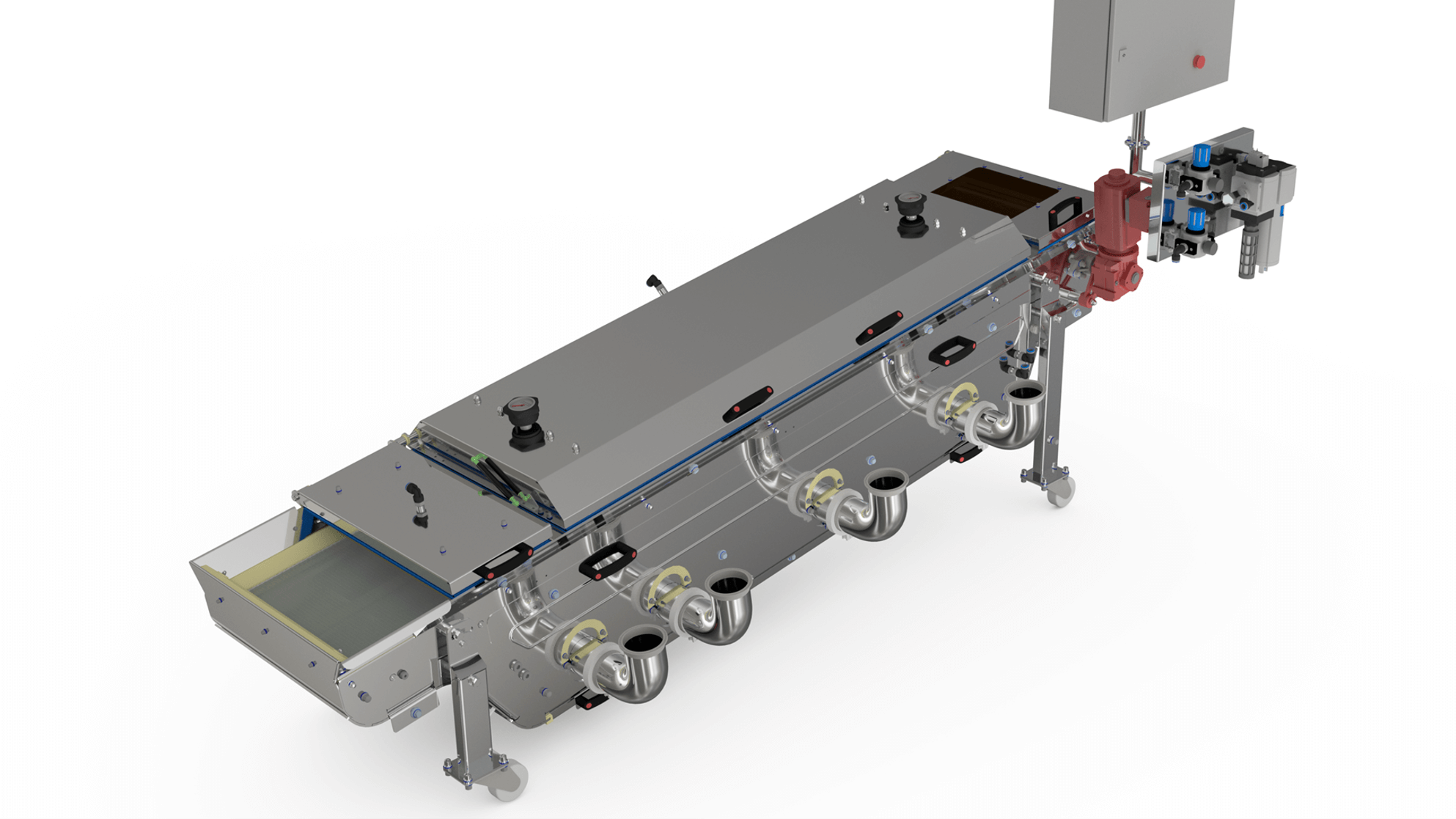

remove all starch from moulded confectioneries

All products in the tna conti-clean solution series provide your line with the means to remove starch from all moulded confectionery products before they go to oiling, sugaring or sanding. The tna conti-clean solution in particular is built with air-operated, high-pressure rotary jets that are mounted both above and below an open-weave wire belt. This ensures starch particles are efficiently and effectively removed from all products as they are transported through the system.

expertly manage and control all oiling processes

The tna conti-oil is equipped with oil polishing, dispensing and electric heating technology to accurately and consistently coat oil on all jelly and gum-based confectionery items. This solution enables your manufacturing teams to add an appealing glaze with a much wider range and depth of colour to your products.

apply consistent sugar coating to all starch-moulded items

Your manufacturing plant can use the tna intelli-coat to apply a consistent sugar coating to starch-moulded items like jelly and gum-based confectioneries. Equipped with independently controlled steam jets, stainless steel steaming conveyors and product supply input sensors, this solution has a delivery capacity of up to 3,600 kg/hr (7,930 lbs/hr) depending on product type.