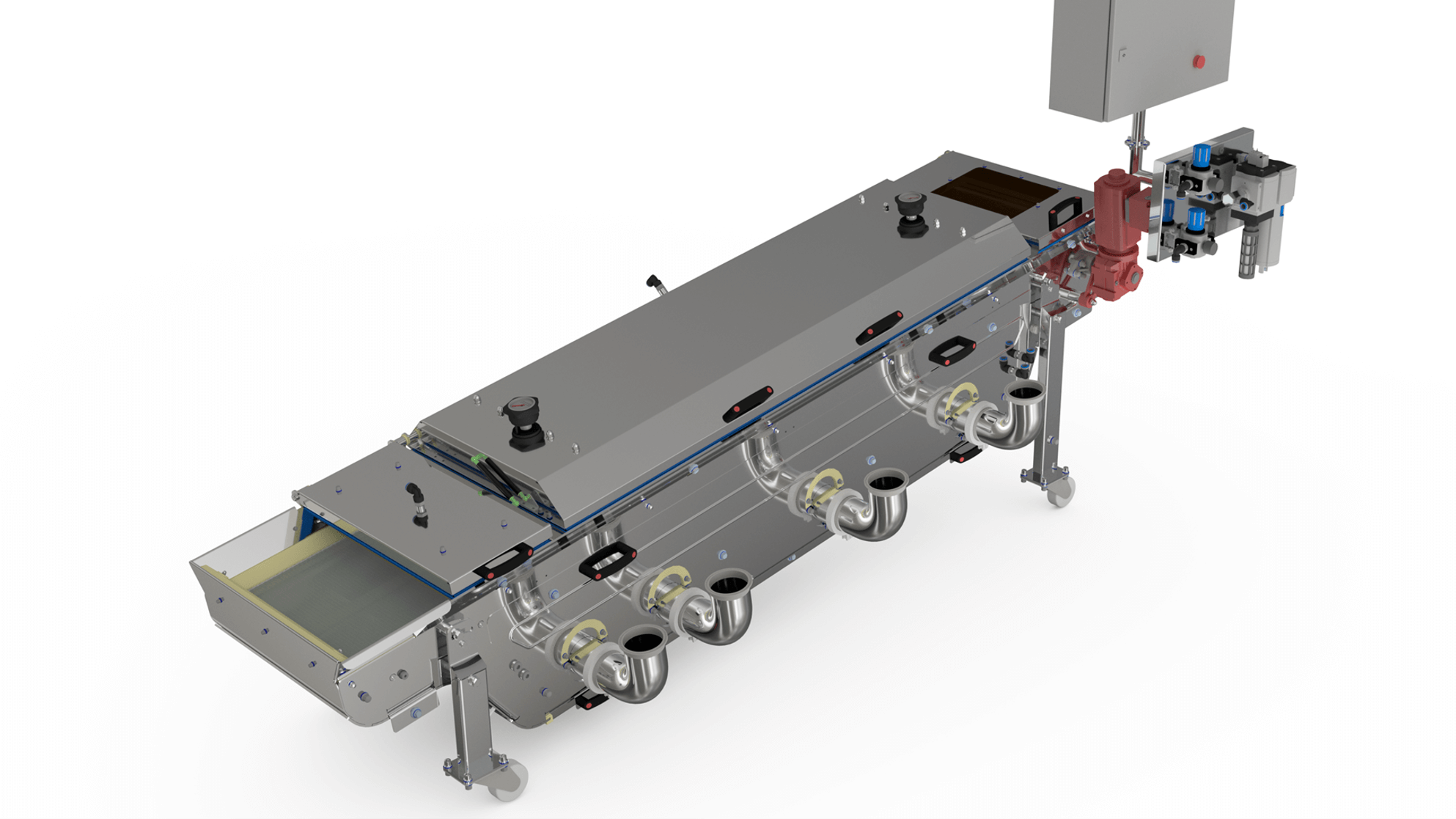

tna conti-clean

The tna conti-clean candy cleaners are high-performance machines that effectively remove starch from moulded confectionery before oiling or sugar sanding. Air-operated high-pressure rotary air-jets mounted above and below an open-weave wire belt ensure the efficient removal of starch articles as they are transported through the system. The tna conti-clean candy cleaners are available in two belt sizes, with double or triple sets of spinning air-jets, to match your chosen production rate.

Removes starch from all product surfaces at production rates of up to 4,500 kg/h (9,900 lbs/hr).

Match production flow to maximise throughput.

Integrate quickly and easily with other moguls and finishing equipment thanks to its compact, simple design.

Operate from an easy-to-use electrical control panel.

- Double air-jets with capacities up to 2200 kg/hr (4850 lbs/hr)

- 400 mm (16 in) wide open-weave, stainless-steel wire belt

- Adjustable belt conveyor height

- Combined air filter and pressure regulator

- Castor mounting

- Acoustic insulation

- Stainless-steel construction

- Internal dust collection cones and external ports to connect a suitable dust collector

- triple air-jets (TLC) with capacities up to 3600 kg/hr (7936 lbs/hr)

- Adjustable, vibratory product feeder to evenly spread out product

- Additional air curtains for extra cleaning

- Dust collector (filter)

| tna conti-clean | ||

|---|---|---|

| model name | DLC (double air-jets) | TLC (triple air-jets) |

| product output kg/hr (lbs/hr) | 2300 (5070) | 3200 (7056) |

| net weight kg (lb) | 250 (550) | 300 (660) |

| width mm (in) | 580 (23) | |

| belt width mm (in) | 400 (16) | |

| Adjustable floor to belt height mm (in) | 850 – 1100 (34 – 43) | |

| air consumption at 6 bar m3/min (cfm) | 2.46 (86.9) | 3.69 (130.3) |

| electrical requirements kW (hp) | 0.37 (0.5) | |

| electrical requirements including optional feeder kW (hp) | 0.75 (1) | |

| recommended dust collector section m3/min (cfm) | 25 (883) | 37.5 (1324) |

| all above specifications are subject to change and may differ according to the product, please confirm when placing your order. | ||

- Gummies & jellies

- Confectionery processing