tna PRESENTS START-TO-FINISH SOLUTIONS AT BTA 2015

events | 6 mins read

April 16, 2015

tna, hall 5 stand C 105, BTA 2015, Gran Via venue – Fira de Barcelona, Barcelona, Spain, 21-24 April 2015

Integrated packaging and processing solutions provider tna will showcase its range of high performance total systems at Barcelona Tecnologías de la Alimentacíon (BTA) 2015 for the very first time. Experts from tna’s global team will present a complete choice of solutions, including the tna robag® FX 3ci high speed vertical form fill and seal (VFFS) packaging system, the tna intelli-flav® OMS 5 on-machine seasoning system and the FOODesign cryo-jet® 5 ambient air cooling system. Visitors to the stand will also be able to learn more about tna’s recent acquisitions of leading food processing specialists, Florigo® and FOODesign, and how this enables tna to further boost its processing capabilities and cement its position as a leading provider of start-to-finish solutions.

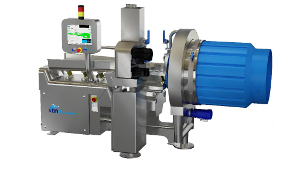

Delivering unrivalled throughput of up to 250 bpm, the tna robag FX 3ci high speed VFFS packaging machine offers production flexibility in a compact, easy-to-clean system that is suitable for a wide variety of products. This cutting edge system provides up to a 30 per cent improvement in performance in terms of output and reduction in rejects, while achieving unprecedented throughput rates. With innovative features including the patented tna hyper-detect® metal detector and the tna intelli-scan® visual print code verification system, the tna robag FX 3ci provides manufacturers with a complete packaging solution. In addition, tna has made it even easier to operate the machine by simplifying the film system. The new tna auto-splice® automatically changes film reels when one is finished, increasing packaging efficiency and product throughput by reducing the need for manual intervention.

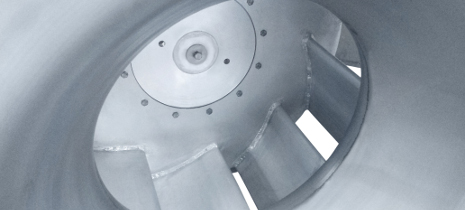

Also on show is the tna intelli-flav OMS 5, a fully integrated oil spray and flavour injection system, which offers consistent coverage and flavour for both wet and dry seasoning. Designed to deliver tna’s renowned combination of performance, simplicity and flexibility, the tna intelli-flav OMS 5 features a responsive variable mass seasoning system with dynamic vibratory weigher to directly control oil spray and powder flow into the drum. This enables an accurate, proportional amount of seasoning to be evenly applied to the product for improved coverage and flavour dispersion.

Visitors to the stand will also be able to experience the FOODesign cryo-jet 5 ambient air cooling system. Utilising patented ambient air impingement technology, the FOODesign cryo-jet 5 cools food products up to ten times faster than systems based on forced convection or natural convection cooling, significantly reducing pre-packaging and pre-freezing cooling times and maintaining product quality.

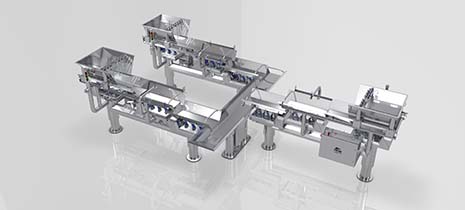

Alongside its existing portfolio of packaging, seasoning and distribution solutions, tna now offers a variety of Florigo’s continuous snack and french fry lines, including patented continuous vacuum frying technology. This coupled with FOODesign’s world leading fryers and cookers, along with batch fryers, continuous fryers, baking and toasting ovens, and speciality roasting equipment, suitable for a variety of applications, means that tna can now offer customers a range of solutions, from smaller direct-fired batch fryers to complete frying production lines with capacities of up to 30,000kg/h, to deliver customised, efficient turnkey solutions.

tna will also highlight its system control and integration expertise. The team will demonstrate the benefits of control systems, such as programmable logic controllers (PLC) and supervisory control and data acquisition (SCADA). These systems are easily integrated into existing production lines giving plant operators the ability to target specific areas where inefficiencies are most prevalent. This ensures that each element of the production line works in harmony with each other, resulting in a fully optimised and seamless operation.

James Hosford, European director of sales at tna comments: “We are very excited to showcase our latest and most innovative products at BTA 2015 for the very first time. Having recently merged with processing specialists FOODesign and Florigo, we are eager to present our extensive range of flexible and high performance start-to-finish solutions to the Spanish market.”

For information and advice on tna’s high performance products and services, visit hall 5 stand C 105 at BTA 2015.

ENDS

Editor’s note:

About tna

tna is a leading global supplier of integrated food packaging and processing solutions with over 7,000 systems installed across more than 120 countries. The company provides a comprehensive range of products including processing, coating, distribution, seasoning, weighing, packaging, metal detection and identification solutions. tna also offers a variety of production line controls, integration and SCADA reporting options. tna’s unique combination of innovative technologies, extensive project management experience and 24/7 global support ensures customers achieve faster, more reliable and flexible food products at the lowest cost of ownership.

About Florigo Industry B.V.:

With over 60 years of experience in the food processing industry, Florigo® (a tna company) is widely known for its ability to boost capacity, improve quality and increase efficiency with its wide range of innovative food processing technology. The company specialises in the design, manufacture and servicing of high-performance processing equipment for the snacks industry, including washing, de-stoning, peeling, slicing, blanching, drying, frying, cooling and freezing equipment. Florigo’s cutting-edge patented vacuum frying and de-fatting technology helps food manufacturers around the world to develop healthier snacks with unique consumer appeal.

About FOODesign:

For over 40 years, FOODesign (a tna company) has been a leading innovator in food processing equipment and solutions for the snacks, meat and poultry, prepared foods, confectionery and bakery industries. Headquartered in Oregon, U.S., the company designs and manufactures heavy-duty, precision-built cooking and processing systems, tailored to customers’ needs. Its high performance products include cooking and baking equipment, fryers, ovens, cooling equipment, seasoning and coating machines, bulk handling conveyors, distribution and storage systems, as well as controls system technology. FOODesign also offers a range of added-value services, including project support and maintenance to ensure optimal performance and maximum return on investment.

For further information, please contact: Michael Lea

TNA Australia Pty Ltd., 24 Carter Street, Sydney Olympic Park NSW, 2127, Australia

Tel: +61 412 366 379 Fax: +61 297 482 970

Email: [email protected] or visit: http://www.tnasolutions.com

Twitter: http://twitter.com/tnasolutions

For further press information, please contact: Emma Simms / Wiebke Thiel

Barrett Dixon Bell Ltd., Craig Court, 25 Hale Road, Altrincham, Cheshire, WA14 2EY, UK

Tel: +44 (0)161 925 4700 Fax: +44 (0)161 925 4701

Email: [email protected] / [email protected]