tna SHOWCASES COMPLETE CAPABILITIES AT GULFOOD MANUFACTURING 2015 FOR THE VERY FIRST TIME

events | 5 mins read

September 15, 2015

tna booth #A3-32, Hall 3, Gulfood Manufacturing 2015, Dubai, UAE, October 27-29, 2015

Last year, tna impressed Gulfood guests with the launch of its tna intelli-weigh 0328 omega multi-head twin scale, but this year, it’s all about showcasing complete turnkey systems solutions for the very first time at Gulfood Manufacturing 2015. Visitors to the stand will be able to explore tna’s product portfolio of complete solutions including processing and packaging equipment, controls integration and SCADA reporting, via the all new tna innovation station. The company is creating a hands-on environment giving Gulfood Manufacturing attendees the ability to interact with complete systems, learn about modular pieces of equipment, zoom in and view specific product information and watch detailed product videos. Alongside on-stand product demonstrations, visitors will be able to discuss requirements with tna’s global team of eight experts, including Mukul Shukla (general manager – Middle East), Moataz Hafez (sales manager – Dubai) and Henk Boon (processing solutions manager – EMEIA).

Last year, tna impressed Gulfood guests with the launch of its tna intelli-weigh 0328 omega multi-head twin scale, but this year, it’s all about showcasing complete turnkey systems solutions for the very first time at Gulfood Manufacturing 2015. Visitors to the stand will be able to explore tna’s product portfolio of complete solutions including processing and packaging equipment, controls integration and SCADA reporting, via the all new tna innovation station. The company is creating a hands-on environment giving Gulfood Manufacturing attendees the ability to interact with complete systems, learn about modular pieces of equipment, zoom in and view specific product information and watch detailed product videos. Alongside on-stand product demonstrations, visitors will be able to discuss requirements with tna’s global team of eight experts, including Mukul Shukla (general manager – Middle East), Moataz Hafez (sales manager – Dubai) and Henk Boon (processing solutions manager – EMEIA).

In the spotlight

In the spotlight at booth #A3-32, Hall 3 will be tna’s flagship high speed vertical form fill and seal (VFFS) packaging machine, the tna robag® FX 3ci. Visitors will be able to witness the equipment in action and discover how tna provides the ultimate flexibility in packaging. Compact, easy-to-clean and designed to package a wide range of applications at rapid speeds, this cutting edge system improves performance up to 30 percent in terms of output and reducing the number of rejects, while achieving unprecedented throughput rates. While at the stand, attendees can interact with tna experts to learn more about the tna robag’s additional innovative features including the tna intelli-weigh® omega 0314 multi-head twin scale, the patented tna hyper-detect® metal detector and tna intelli-read® bar code verification scanning system. In addition, tna has made it even easier to operate the machine by simplifying the film system. The tna auto-splice® now automatically changes film reels when one is finished, increasing packaging efficiency and product throughput by reducing the need for manual intervention. These are all part of tna’s complete packaging solution for manufacturers.

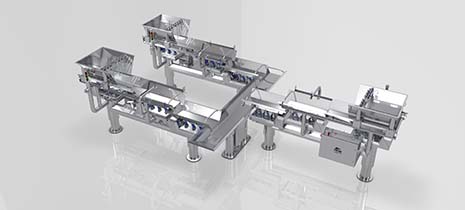

Together with tna’s complete line via the new tna innovation station, manufacturers can also experience some of tna’s most innovative equipment on the stand including:

tna intelli-flav® OMS 5: ultimate on-machine seasoning system that can provide both powder flavouring and liquid oil in a single drum to deliver consistent coverage and flavour to your product.

tna roflo® HM 3: horizontal motion distribution system designed to minimise product loss with low force operation and total control over speed and direction.

FOODesign cryo-jet® 5: Ambient air cooling system for the rapid cooling of baked and fried snack foods using only ambient air.

Controls integration and SCADA reporting: extensive range of integrated controls solutions, site support, project management and training services.

General manager for tna Middle East, Mukul Shukla, comments: “We’re always very excited to come back to Gulfood Manufacturing ? it’s such a dynamic, successful show and a perfect occasion for our customers in the region to meet our team of experts and take advantage of their impressive knowledge of the packaging and processing industry.”

He adds: “We look forward to the interaction with our booth visitors, hearing about their challenges, their successes and what their needs are. Due to an increasing demand for simple, flexible and high performing systems in the region, manufacturers benefit from having a single source supplier that can provide a comprehensive range of start-to-finish solutions for all their applications.”

For information and advice on tna’s high performance products and services, visit booth #A3-32, Hall 3 at Gulfood Manufacturing, visit tnasolutions.com or email [email protected] to schedule an appointment.

END

Editor’s note:

About tna:

tna is a leading global supplier of integrated food packaging and processing solutions with over 7,000 systems installed across more than 120 countries. The company provides a comprehensive range of products including materials handling, processing, coating, distribution, seasoning, weighing, packaging, cooling, freezing, metal detection and verification solutions. tna also offers a variety of production line controls integration & SCADA reporting options, project management and training. tna’s unique combination of innovative technologies, extensive project management experience and 24/7 global support ensures customers achieve faster, more reliable and flexible food products at the lowest cost of ownership.

About FOODesign:

FOODesign (a tna company) is a leading innovator in food processing equipment and solutions. The company manufactures heavy-duty precision built cooking and processing machines at an affordable price. Products include cooking and baking equipment, fryers, ovens, cooling equipment, seasoning and coating machines, bulk handling conveyors, distribution and storage systems, as well as controls system technology. In addition, FOODesign offers a range of added-value services including project support and maintenance to ensure optimal performance.

About Florigo Industry B.V.:

With over 60 years of experience in the food processing industry, Florigo Industry (a tna company) is widely known for its ability to boost capacity, improve quality and increase efficiency with its wide range of innovative food processing technology. The company specializes in the design, manufacture and servicing of high-performance processing equipment for the snacks industry, including washing, de-stoning, peeling, slicing, blanching, drying, frying, cooling and freezing equipment. Florigo’s cutting-edge patented vacuum frying and de-fatting technology helps food manufacturers around the world to develop healthier snacks with unique consumer appeal.

For further information, please contact: Michael Lea

TNA Australia Pty Ltd., 24 Carter Street, Sydney Olympic Park NSW, 2127, Australia

Tel: +61 412 366 379 Fax: +61 297 482 970

Email: [email protected] or visit: www.tnasolutions.com

Twitter: http://twitter.com/tnasolutions

For further press information, please contact: Emma Simms / Bérengère Vinsant,

Barrett Dixon Bell Ltd., Craig Court, 25 Hale Road, Altrincham, Cheshire, WA14 2EY, UK

Tel: +44 (0)161 925 4700 Fax: +44 (0)161 925 4701

Email: [email protected] / [email protected]