tna’s new energy-efficient freezer fan design reduces energy consumption by more than 30% for a more sustainable french fry production

products | 3 mins read

August 28, 2017

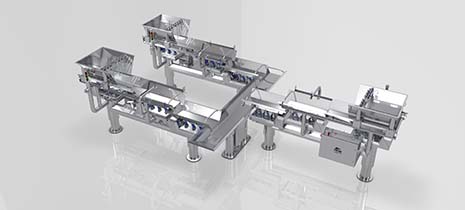

Sydney, Australia, 28 August 2017 – tna has introduced a new energy-efficient fan design for its Ferguson ener-freeze® FFV 3 to reduce energy consumption by more than 30%, providing French fry manufacturers with a more cost-effective and sustainable freezing solution. Featuring the latest airflow technology, the Ferguson ener-freeze FFV 3 is able to evenly freeze a variety of potato products in different shapes, including sticks, cubes and wedges. As part of tna’s commitment to continuous innovation and a sustainable production process, the company has now developed a new energy-efficient freezer fan to reduce operating costs and increase production cycles while ensuring a high quality and uniformly frozen product.

Sydney, Australia, 28 August 2017 – tna has introduced a new energy-efficient fan design for its Ferguson ener-freeze® FFV 3 to reduce energy consumption by more than 30%, providing French fry manufacturers with a more cost-effective and sustainable freezing solution. Featuring the latest airflow technology, the Ferguson ener-freeze FFV 3 is able to evenly freeze a variety of potato products in different shapes, including sticks, cubes and wedges. As part of tna’s commitment to continuous innovation and a sustainable production process, the company has now developed a new energy-efficient freezer fan to reduce operating costs and increase production cycles while ensuring a high quality and uniformly frozen product.

The Ferguson ener-freeze FFV 3 features centrifugal fans with curved blades to optimise the air flow underneath the belt, resulting in even air velocity over the product for a high heat transfer rate and even fluidisation across the entire width of the belt. As the air speed is near the product’s fluidisation velocity, the appearance of clusters is eliminated and each French fry is frozen individually, quickly and to perfection.

In addition, the specific impeller construction of the Ferguson ener-freeze FFV 3 ensures that the fan curve has almost 100% spare static pressure to minimise the effects of production fluctuations and ensure a more stable fan curve over an increased period of time. As a result, the Ferguson ener-freeze FFV 3 reduces power consumption by more than 30% compared to previous technology and can maintain an efficient performance for longer before it requires defrosting, significantly increasing production cycles.

“Pre-coolers and freezers are some of the biggest power consumers in any French fry line,” comments Henk Boon, group solutions manager – processing at tna. “These systems often require high volumes of electric power to operate and also to cool down the heat they release in exchange. Reducing the power consumption of this type of equipment not only results in immediate energy savings, but will also have a significant influence on the overall operational costs of the entire production line. In fact, by upgrading their equipment to the Ferguson ener-freeze FFV 3, manufacturers can expect a return on investment in only one to two years. This, in combination with shorter cleaning periods, reduced maintenance and superior equipment reliability, make the Ferguson ener-freeze FFV 3 a valuable addition to any French fry production line.”

Ferguson, a tna brand, have been supplying the French fry industry for over 30 years, developing some of the industry’s most innovative designs. Renowned for their performance, reliability and low energy consumption, Ferguson cooling and freezing tunnels are the ideal solution for a wide variety of potato products.

ENDS

About tna

tna is a leading global supplier of integrated food processing and packaging solutions with 35 years of industry experience and over 14,000 systems installed across more than 120 countries. The company provides a comprehensive range of products including materials handling, processing, cooling and freezing, coating, distribution, seasoning, weighing, packaging, inserting and labelling, metal detection, verification and end of line solutions. tna also offers a variety of production line controls integration & SCADA reporting options, project management and training. tna’s unique combination of innovative technologies, extensive project management experience and 24/7 global support ensures customers achieve faster, more reliable and flexible food products at the lowest cost of ownership.

For further information, please contact: Ms. Wiebke Thiel

tna solutions Pty Ltd., 24 Carter Street, Sydney Olympic Park NSW, 2127, Australia

Tel +61 412 366 379 Fax +61 297 482 970

Email wiebke.thiel@tnasolutions.com or visit www.tnasolutions.com

Twitter http://twitter.com/tnasolutions