tna and NID to introduce the latest confectionery solutions at interpack

events | 5 mins read

April 13, 2017

Leading food processing and packaging equipment supplier tna and confectionery specialist NID to present the latest mogul technology and introduce a new, innovative approach to gummy polishing

NID (from tna), hall 3, booth D29, interpack, Düsseldorf, Germany, 4-10 May, 2017

Sydney, Australia, 13 April 2017 – tna, together with the newest member of its family of brands NID, a leading developer of starch moulding technology, will display the latest cutting-edge solutions for the confectionery industry at this year’s interpack show in Düsseldorf, Germany. Highlights at booth 3D29 will include the latest version of NID’s flagship starch mogul, the NID M3000, tna’s innovative intelli-flav® OMS 5 system, which is now also available for the oiling and polishing of gummy applications, and the leading tna robag® FX 3ci vertical form fill and seal system for the high-speed bagging of a wide range of confectionery products.

The latest starch moulding technology

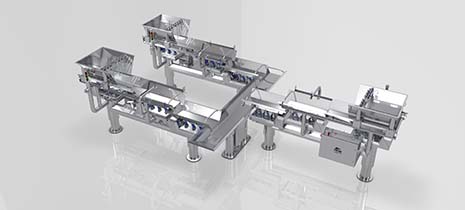

A fully integrated and automated solution, comprising feeder, starch buck, depositor and stacker, the NID M3000 processes a multitude of single and multilayer starch-moulded products such as gums, jellies, marshmallows, fondant creams, liquorice and crusted liqueur, including striped and centre-in-shell products. The latest version of this starch moulding equipment now comes with a range of new innovative features, enabling it to achieve faster production speeds, while offering customers some of the highest levels of product versatility and operational reliability.

“We’re really excited to return to this year’s interpack with the latest generation of our M3000 mogul,” comments Mark Mueller, CEO at NID (from tna). “Our engineers have been extremely busy over the last few months to equip our flagship mogul with some exciting new features, including an automatic starch gate, a modular depositor frame and high speed turntable demoulding, offering manufactures some of the highest levels of speed and flexibility on the market.”

An innovative approach to oiling/polishing

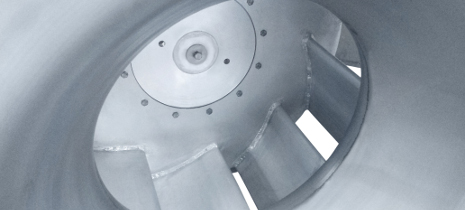

For the first time, manufacturers of gum-based confectionery will also be able to find out how tna’s innovative intelli-flav OMS 5 and its integrated mass flow controlled oil injection system can help them gain tighter control over their oiling/polishing processes. Contrary to conventional oiling methods that require the candy to be retained in the tumble drum over a set period of time, the tna intelli-flav OMS 5 makes it possible to oil and polish the articles by simply feeding them through the system’s rotating drum, significantly reducing retention time and avoiding any potential damage to the product. At the same time, the system’s precise recipe control has the capacity to eliminate manual intervention in the oiling process, ensuring that only the right amount of oil is used for the highest levels of product consistency.

“Interpack has always been an important show for us and thanks to our recent acquisition of NID, we’re now able to present the confectionery industry with a much wider range of solutions,” adds Mark Lozano, sales manager at tna. “More importantly, it’s a great platform to show confectionery manufacturers how tna’s innovative equipment solutions have the potential to revolutionise their current manufacturing processes. Our tna intelli-flav OMS 5 is the perfect example of the synergies between NID and tna, but it’s only the beginning! It’s an exciting time for us and our customers and we can’t wait to start demonstrating the unique benefits of our complete range of packaging and processing solutions.”

High-speed bagging solutions

Visitors to the booth will also get a chance to see the world’s fastest packaging system in action. Part of tna’s range of high performance packaging solutions, the revolutionary tna robag FX 3ci vertical, form, fill and seal system is designed to package at industry-leading speeds from a single tube, using a triple rotary jaw configuration. With its innovative features, including the tna intelli-weigh® 0120 omega multi-head scale, the tna robag is the ideal solution to bag high volumes of sweets, whilst lowering wastage below 0.5% for a continuously high quality and efficient packaging process.

For more information on tna’s complete range of food processing and packaging solutions, visit the tna stand in hall 15, booth B22.

ENDS

About tna

tna is a leading global supplier of integrated food processing and packaging solutions with over 14,000 systems installed across more than 120 countries. The company provides a comprehensive range of products including materials handling, processing, cooling and freezing, coating, distribution, seasoning, weighing, packaging, inserting and labelling, metal detection and verification solutions. tna also offers a variety of production line controls integration & SCADA reporting options, project management and training. tna’s unique combination of innovative technologies, extensive project management experience and 24/7 global support ensures customers achieve faster, more reliable and flexible food products at the lowest cost of ownership.

About NID

Having served the confectionery industry for over 60 years, NID (from tna) is a specialist in the manufacture of starch moulding and ancillary equipment with more than 600 NID moguls installed across the globe. The company offers all the equipment required for starch moulding, including moguls, laboratory printer depositors, depositing pumps and accessories, starch conditioning systems and an array of product finishing equipment to clean, oil or sugar coat products.

For further information, please contact: Ms. Wiebke Thiel

tna solutions Pty Ltd., 24 Carter Street, Sydney Olympic Park NSW, 2127, Australia

Tel +61 412 366 379 Fax +61 297 482 970

Email [email protected] or visit www.tnasolutions.com

Twitter http://twitter.com/tnasolutions