tna PRESENTS COMPLETE LINE OF TURNKEY SOLUTIONS AT FISPAL TECNOLOGIA 2016

events | 5 mins read

May 20, 2016

Leading processing and packaging provider showcases complete line for the food industry, including new interactive experience

tna stand #B-061, Fispal Tecnologia, Sao Paulo, Brazil, 14-17 June 2016

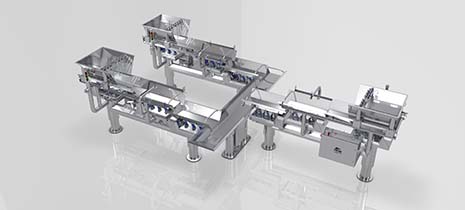

Leading global processing and packaging provider tna will highlight its innovative turnkey solutions at this year’s Fispal Tecnologia, the largest and most complete event for the food industry in Latin America. Visitors can familiarise themselves with tna’s complete line of processing and packaging solutions via the all-new tna innovation station, a fully interactive experience. Here, visitors can access a 3D view of tna’s food processing and packaging line, from start to finish, including individual solutions, zoom in for a more detailed view, pan out for an entire production line overview and watch product videos.

There will also be live product demonstrations of tna’s most innovative technology, including the revolutionary tna robag® FX 3ci, to show visitors how they can make the most of the vast opportunities in this booming sector. Attendees can also discuss their processing and packaging requirements with tna’s global experts, Thiago Roriz, general manager for Latin America and Patrick Avelange, general manager for the Americas.

Thiago Roriz comments: “We’re thrilled to return to Fispal Tecnologia. It’s a key event in the tna calendar and a perfect opportunity for us to showcase our complete line of processing and packaging solutions to food manufacturers across the region. With the recent additions of FOODesign, Florigo and Unique Solutions to the tna family, we now offer customers a complete one-stop shop for food production equipment and solutions across a wide variety of applications.”

Roriz adds: “The Latin American food industry is booming and companies are increasingly looking to maximise the performance of their entire production line whilst minimising costs. In addition, there is an increased demand for flavoured snack applications. tna is perfectly placed to meet these demands and our innovation station will give visitors the chance to explore this, by viewing our entire production line through a unique interactive experience.”

Start-to-finish solutions for the entire food industry

On display at stand #B-061 will be tna’s flagship high speed vertical form fill and seal (VFFS) packaging machine, the tna robag FX 3ci. Compact, easy-to-clean and designed to package a wide range of applications at rapid speeds, this cutting edge system improves performance up to 30 per cent in terms of output and reduces the number of rejects, while achieving unprecedented throughput rates.

While at the stand, attendees can also learn more about its innovative features, including the tna intelli-weigh® omega 0314 multi-head scale, the patented tna hyper-detect® metal detector and tna intelli-read® bar code verification scanning system. tna has also made it even easier to operate the machine by simplifying the film system. The tna auto-splice® now automatically changes film reels when one is finished, increasing packaging efficiency and product throughput by reducing the need for manual intervention. These are all part of tna’s complete packaging solutions for snack manufacturers.

In addition, manufacturers can also experience tna’s ever expanding product portfolio including:

tna intelli-flav® OMS 5: ultimate on-machine seasoning system that can provide both powder flavouring and liquid oil in a single drum delivering consistent coverage and flavour to your product.

tna roflo® HM 3: horizontal motion distribution system designed to minimise product loss with low force operation and total control over speed and direction.

FOODesign cryo-jet® 5: ambient air cooling system for the rapid cooling of baked and fried snack foods using only ambient air, offering manufacturers the potential to cool up to ten times faster than other cooling systems.

On-stand spray display: innovative application of oils using tna’s high performance spinning disc spraying technology and variety of options for spray nozzles.

Controls integration and SCADA reporting: extensive range of integrated controls solutions, site support, project management and training services.

For more information on tna’s complete portfolio of turnkey solutions and services, please visit tna stand #B-061, visit www.tnasolutions.com or email info@tnasolutions.com to schedule an appointment.

ENDS

About tna

tna is a leading global supplier of integrated food processing and packaging solutions with over 14,000 systems installed across more than 120 countries. The company provides a comprehensive range of products including materials handling, processing, cooling and freezing, coating, distribution, seasoning, weighing, packaging, inserting and labelling, metal detection and verification solutions. tna also offers a variety of production line controls integration & SCADA reporting options, project management and training. tna’s unique combination of innovative technologies, extensive project management experience and 24/7 global support ensures customers achieve faster, more reliable and flexible food products at the lowest cost of ownership.

For further information, please contact: Wiebke Thiel

TNA Australia Pty Ltd., 24 Carter Street, Sydney Olympic Park NSW, 2127, Australia

Tel +61 412 366 379 Fax +61 297 482 970

Email [email protected] or visit www.tnasolutions.com

Twitter http://twitter.com/tnasolutions

For further press information, please contact: Emma Simms / Bérengère Vinsant

Barrett Dixon Bell Ltd., Craig Court, 25 Hale Road, Altrincham, Cheshire, WA14 2EY, UK

Tel +44 (0)161 925 4700 Fax +44 (0)161 925 4701

Email [email protected] / [email protected]