TNA Solutions to spotlight complete snack and confectionery line solutions at Gulfood Manufacturing 2025

October 9, 2025

Visit stand A4-4, Hall 4 | 4 – 6 November | Dubai, UAE

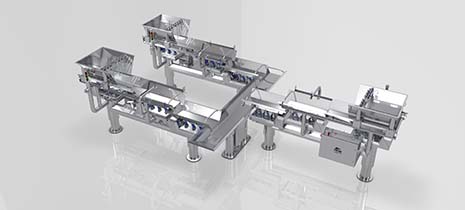

Dubai, United Arab Emirates, 9 October 2025 – TNA Solutions, a global leader in complete processing and packaging, will highlight its complete line solutions for snacks and confectionery at Gulfood Manufacturing 2025 (Stand A4-4, Hall 4). With decades of global expertise and a strong track record in both greenfield and brownfield projects across the Middle East and Africa, TNA will demonstrate how its holistic approach helps producers simplify operations, reduce costs, and accelerate growth. In addition, TNA’s integrated distribution, seasoning, and packaging systems enable rapid introduction of new flavours, formats, or seasonal runs, all while minimising downtime and footprint.

The stand will showcase exhibits from TNA’s portfolio, including the company’s flagship tna robag® 3e vertical form fill and seal (VFFS) packaging system, capable of producing up to 250 bags per minute with industry-leading accuracy and waste levels as low as 0.1%.

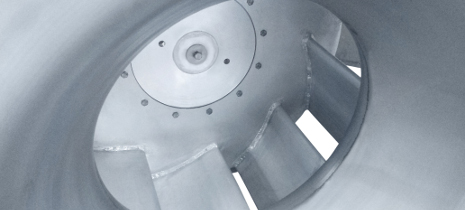

Visitors will also see the tna intelli-flav® OMS 5.1 on-machine seasoning system, which offers mass-based gravimetric control for precise application of dry, wet/oil, or slurry coatings in a single drum. Intelligent control and monitoring software ensures quick recipe adjustments and high-speed operation, allowing brands to respond efficiently to changing consumer demands.

“Snacks and confectionery markets are booming in the MEA region, with consumers looking for variety and premium appeal,” said Palani Karai, General Manager – TNA Solutions, MENA. “At the same time, producers are under pressure to manage more SKUs, shorter runs, and rapid changeovers – often with fewer staff. Meeting these challenges requires more than machinery. It demands a partner with global knowledge, local expertise, and accountability for every stage of the line. That’s where TNA Solutions comes in.”

Integrated systems benefits

By synchronising every element of distribution, seasoning, and packaging, TNA empowers producers to:

- Maximise output with reduced downtime

- Lower total cost of ownership with fewer standalone machines

- Achieve faster, simpler changeovers across multiple SKUs

- Reduce waste through precise product handling and flavour control

- Improve labour efficiency with automation and unified controls

A complete solutions partner

TNA’s complete line approach ensures that food production is efficient today and ready for tomorrow. With modular, scalable solutions, producers can accelerate launches, maintain premium quality, and expand capacity with confidence.

To find out more about TNA’s complete line solutions, visit A4-4, Hall 4 at Gulfood Manufacturing from 4–6 November. Register here.