tna TRANSFORMS SNACK MANUFACTURER’S LEAD TIME WITH INNOVATIVE SEASONING SOLUTIONS

company news | 6 mins read

July 7, 2016

Leading processing and packaging solutions supplier, tna works with Brandneu to enhance its production capabilities with new installation

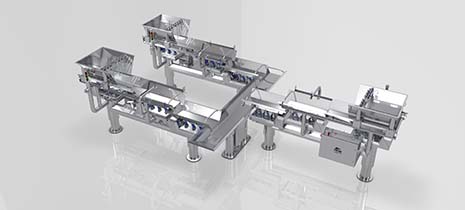

Canadian-based Brandneu Foods significantly reduced lead times for its popular range of kale chips by 75 per cent after installing the high performance tna intelli-flav® OMS 5 at its plant in Toronto. In addition to cutting production lead times from 60 days to just 15, the new installation enabled Brandneu to consolidate work space, meaning it can better respond to customer demands for its products. To ensure a smooth installation, tna provided total project management services—from start to finish, offering Brandneu complete peace of mind to concentrate on their day-to-day business objectives.

Canadian-based Brandneu Foods significantly reduced lead times for its popular range of kale chips by 75 per cent after installing the high performance tna intelli-flav® OMS 5 at its plant in Toronto. In addition to cutting production lead times from 60 days to just 15, the new installation enabled Brandneu to consolidate work space, meaning it can better respond to customer demands for its products. To ensure a smooth installation, tna provided total project management services—from start to finish, offering Brandneu complete peace of mind to concentrate on their day-to-day business objectives.

Innovative solutions to meet increased demand

As a leading supplier of kale chips, Brandneu prides itself on the natural, healthful profile and high quality of its products. Due to increased demand from consumers for healthier alternatives to potato chips, Brandneu has seen the popularity of its kale chips soar. The company therefore needed to reassess its production capabilities to meet this demand and stay competitive, in an increasingly crowded market place.

“The current trend towards healthier snacks has had a key influence on the food industry,” comments Sekhar Chakkingal, regional sales manager, tna North America. “Consumers are growing more and more concerned about the amount of fat, sugar and salt they consume. As a result, many manufacturers like Brandneu are looking for innovative technologies to help them produce healthier, tastier snacks to meet this demand. When approached by Brandneu, tna had exactly the right cutting-edge technology to optimise the production of their natural baked kale chips.”

Improving seasoning accuracy

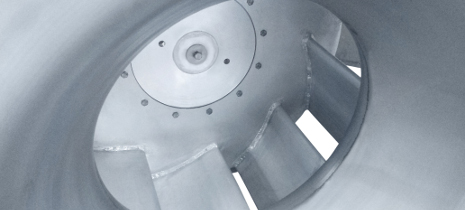

vibratory weigher to directly control oil spray. This means only the right amount of oil is applied to each chip, an essential feature for Brandneu, who were keen to maintain the healthy profile of their popular kale chips.

Thanks to the system’s unparalleled application accuracy Brandneu was able to minimise seasoning losses in the production process, reducing raw material waste and increasing profitability. In addition, the tna intelli-flav OMS 5 offers improved coverage and flavour dispersion, enabling Brandneu to apply minimal salt and flavouring without compromising on the overall quality and taste of its kale chips.

Increasing production speeds

To meet the high demand for their product, Brandneu needed complete flexibility to change flavours quickly and easily. Addressing this need, tna suggested a second drum that can be changed on the line in less than 15 minutes. The addition of the second drum means Brandneu can meet orders more quickly and reduce production lead time considerably. This boost in production offers real customer satisfaction and shows that Brandneu can be relied on to fulfil orders in a short turnaround time.

Adding a completely new system to its existing production line, Brandneu was looking for equipment that was intuitive and easy to use for all operators. tna recognised that in a fast flowing manufacturing process, waiting for the right specialist to operate a machine is going to have a significant time impact. The tna intelli-flav OMS 5 system features a simple touchscreen that is user friendly and easy to programme for simple operation. This helps plant managers save time in training staff, while also providing total peace of mind.

Seamless integration

As Brandneu was looking to maximise floor space for possible future expansions, tna needed to consider the overall footprint of the factory when planning the installation. Brandneu appreciated that, in addition to being simple and easy to use, the tna intelli-flav OMS 5 took up much less space than existing equipment, which provided them with the flexibility to add more lines in the future.

Installed as part of a larger configuration, it was imperative for tna to integrate the machine with other equipment effortlessly. By analysing Brandneu’s existing assets from start to finish, including its operational requirements and training needs, tna’s project management team developed a solution that integrated quickly and seamlessly alongside Brandneu’s existing equipment.

Adrian Quinn, president at Brandneu Foods comments: “Naturally, any production interruptions can be costly for manufacturers. We were very pleased with the speed at which the equipment was installed. Effectively acting as a “plug and play” system, the line was up and running again within a few hours.”

Meeting long-term customer needs

“At tna, our focus is to find the right solutions to our customers’ challenges,” adds Sekhar. “The snack food market is expanding rapidly and Brandneu approached tna because they needed to stay ahead of the curve. Once we assessed their needs, we were able to provide a flexible, high performance solution that meets their long-term production needs.”

Quinn adds: “We’re delighted with the results of the installation from tna. 33 per cent of US consumers are snacking on healthier foods this year compared to last year[1], highlighting an enormous opportunity for us to increase our market share in this growing segment. The tna intelli-flav OMS 5 system better places us to respond to this demand, reducing production lead time by 75 per cent and boosting productivity.”

He continues: “The system has integrated effortlessly into our existing line, is simple to use, easy to clean and most importantly, exceptionally reliable, which as a busy snack producer is imperative to meet customer needs. The service offered by tna is truly excellent, and it’s reassuring to know that we’re supported in every way.”

For more information on tna’s complete portfolio of turnkey solutions and services, please visit www.tnasolutions.com.

[1] Mintel, A snacking nation: 94% of Americans snack daily (July 2015), accessed: http://www.mintel.com/press-centre/food-and-drink/a-snacking-nation-94-of-americans-snack-daily

ENDS

About tna

tna is a leading global supplier of integrated food packaging and processing solutions with over 14,000 systems installed across more than 120 countries. The company provides a comprehensive range of products including materials handling, processing, cooling and freezing, coating, distribution, seasoning, weighing, packaging, inserting and labelling, metal detection and verification solutions. tna also offers a variety of production line controls integration & SCADA reporting options, project management and training. tna’s unique combination of innovative technologies, extensive project management experience and 24/7 global support ensures customers achieve faster, more reliable and flexible food products at the lowest cost of ownership.

For further information, please contact: Wiebke Thiel

TNA Australia Pty Ltd., 24 Carter Street, Sydney Olympic Park NSW, 2127, Australia

Tel +61 412 366 379 Fax +61 297 482 970

Email [email protected] or visit www.tnasolutions.com

Twitter http://twitter.com/tnasolutions

For further press information, please contact: Neil Robertson / Bérengère Vinsant

Barrett Dixon Bell Ltd., Craig Court, 25 Hale Road, Altrincham, Cheshire, WA14 2EY, UK

Tel +44 (0)161 925 4700 Fax +44 (0)161 925 4701

Email [email protected] / [email protected]