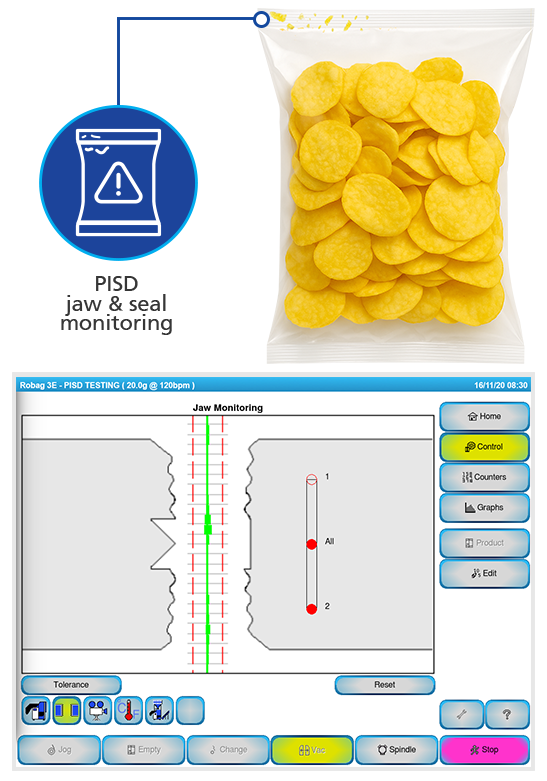

Product in seal detection (PISD)

Available for tna robag® systems, PISD monitors the jaw and seal area in real time to detect faults caused by product in the seal or improper film folding, such as pleats. When a defined number of seal points fall outside preset tolerances, the faulty bag is ejected by the optional reject system — helping reduce waste and maintain consistent pack quality. This ensures only high-quality bags continue downstream.

PISD also provides insights into how sealing performance is impacted by changes in product and environmental conditions — enabling operators to identify issues and take action in real time. Integrate PISD with your factory data systems to capture live QA insights and traceable, line-wide process optimisation.

Detects and logs end seal faults in real time to reduce waste and maintain consistent pack quality

Visually indicates in-seal fault locations in the jaws, and when jaws require cleaning.

Ejects faulty bags automatically using the optional reject mechanism — ensuring only high-quality packs move downstream.

Real-time insights into how changing conditions and product is impacting seal quality and consistency.

Runs on tna robag® without speed restrictions or additional hardware footprint.

- Jaw and seal area monitoring with real-time seal fault detection

- Detects product in seal and pleats.

- Modbus integration for data logging for QA and performance insights.

- Supports QA traceability and reporting.

- PISD is available as a software function for tna robag® 3, 3c, 3ci and 3e.

Options

- PISD reject kit

- The reject mechanism is an ‘air knife’ that automatically ejects faulty bags from the conveyor when a seal error is detected. Ensuring that only properly sealed bags proceed downstream.

| Order codes | |

|---|---|

| TNA0066351 | PISD upgrade for tna robag® 3 and 3ci |

| TNA0099886 | PISD upgrade for tna robag® 3e |

Other PISD options also available, including:

- PISD reject mechanism kit

- tna intelli-speed

Contact your local TNA office for more information.