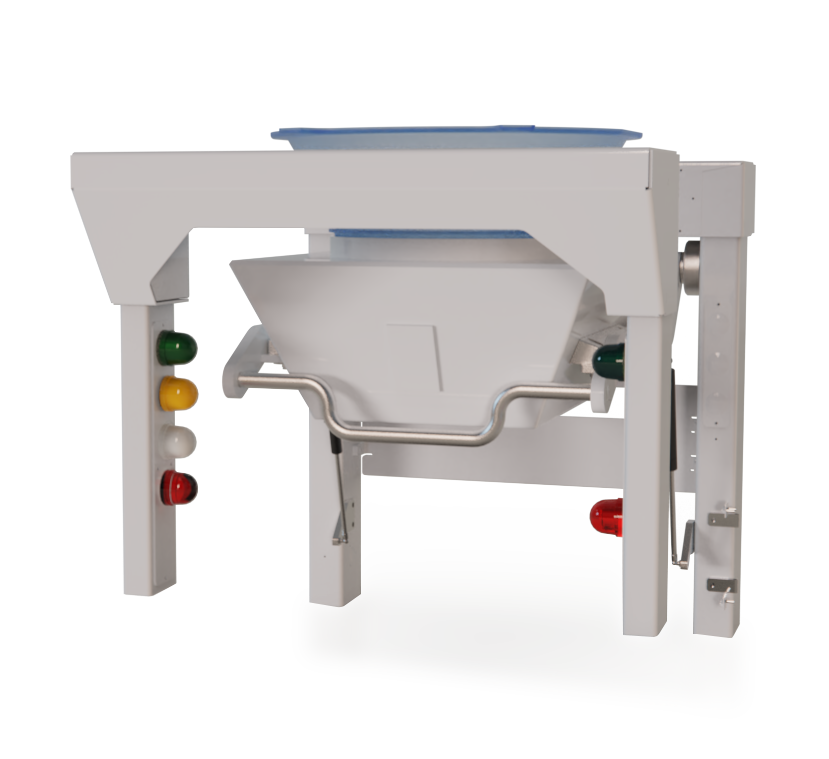

tna hyper-detect® 5

Protect your brand reputation and consumer trust with the tna hyper-detect® 5. Featuring the world’s first non-symmetrical balanced coil with a conical aperture, it delivers unrivalled sensitivity at ultra-high speed, catching ferrous contaminants other systems might miss. Prevent costly recalls and reputational damage while boosting efficiency, maximising uptime, and ensuring consistent product quality.

Protect revenue and brand equity – by preventing contamination incidents that could trigger recalls, lawsuits, or retailer delistings.

Maximise throughput and operational efficiency – maintain ultra-high speeds (up to 250 bpm*) with no compromise on detection sensitivity.

Increase profitability and ROI – advanced coil reduces false rejects, waste and downtime, ensuring faster payback and stronger margins.

Reduce cost and complexity of ownership – compact integration and reliability lower total cost of ownership over the equipment’s life.

Comply with industry requirements for HACCP and GFSI standards.

Compatible with the full range of tna robag® bagmakers.

*Speeds determined by bag size, jaws, film, product type and line configuration.

- Ultra-sensitive contaminant detection

Identifies contaminants down to 0.8 – 0.9 mm, non-ferrous to 1.0 mm, and stainless steel to 1.0 – 1.2 mm. - Non-symmetrical balanced coil with conical aperture delivers accurate detection at up to 250 bpm*.

- Patented design with reduced stack height allows installation directly between the weigher and bagmaker without increasing system height.

- In-line validation and test routines with user-replaceable modules – simplifying compliance checks while reducing downtime and service costs.

- Full integration with tna robag® range of bagmakers

- Touchscreen options – choose between a modern, intuitive HMI touchscreen interface for ease of use or a robust membrane keypad for reliable operation in harsher conditions.

| tna hyper-detect® 5 | |

|---|---|

| Metal Contaminate | Typical hyper metal detector sensitivity |

| ferrous using test sample ball mm (in) | 0.8* (0.03)* – 0.9 (0.04) |

| non ferrous using test sample ball mm (in) | 1.0 (0.04) |

| non-magnetic stainless steel using test sample ball mm (in) | 1.0* (0.04)* – 1.2 (0.1) |

| * with tna center cone fitted | |

| all above specifications are subject to change and may differ according to product, please confirm when placing your order. | |

- Dal

- French fries

- Gummies & jellies

- Other Snacks

- Pellets - dry

- Pork rinds

- Potato chips

- Tortilla chips

- Packaging systems