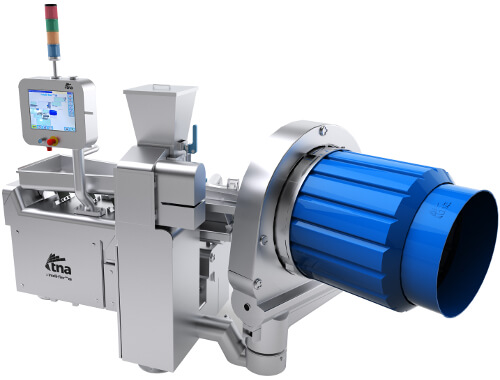

tna intelli-flav OMS 5

Deliver consistent coverage and flavour every time with the tna intelli-flav® OMS 5. This on-machine seasoning (OMS) system features a responsive variable mass seasoning function with a dynamic vibratory weigh conveyor, to directly control product, oil spray and flow of seasoning powder into a single drum. Its innovative design enables an accurate proportional amount of seasoning to be evenly applied to products according to the demand of the scale or bagger – for improved coverage and flavour dispersion.

Create amazing flavours, looks and texture with perfect and consistent seasoning through gentle product tumbling at optimal speeds.

Experience ultimate operational efficiencies by accurately seasoning wet, dry and slurry applications in a single drum.

Realise faster return on investment by minimising seasoning waste and giveaway using our unique responsive variable mass seasoning system.

Capitalise on the unique tna design that enables accurate seasoning of widest possible range of hot or cold products in a single drum reducing the total cost of ownership.

Achieve OEE goals with the up-time advantages of rotating touchscreen that’s accessible from both sides and tool-less drum changeover.

Make the production line operator friendly with the ergonomically designed light weight drum that reduces human effort and time in cleaning and product changeovers.

- Quick release, lightweight, polymer flavour drum

- Screw seasoning hopper and auger

- Volumetric control:

- spice run out detection

- rat-holing detection

- independent bias cut seasoning feeder

- tna roflo® VM 3 control and weigh conveyor

- Loss in weight powder feeder

- Feed conveyors

- Integrated spray system

- LIS module – flavour liquid injection system

- Bulk fill system

- Dust extraction

- Integration with tna robag® and roflo® systems

| tna intelli-flav ® OMS 5 | ||||

|---|---|---|---|---|

| product examples | popped chips | potato chips | corn chips | nuts |

| bulk density g/L (oz/gal) | 55 (7.3) | 65 (8.7) | 75 (10) | 200 (26.7) |

| dry capacity kg/hr (lb/hr) | 550 (1213) | 650 (1433) | 750 (1653) | 1000 (2204) |

| oil application rate kg/hr (lbs/hr) | 2.5 to 49 (5.5 to 108) | |||

| liquid flavour injection rate g/hr (lbs/hr) | 540 to 10,800 (1.2 to 23.8) | |||

| seasoning rate kg/hr (lb/hr) | 0 – 60 (0 – 132) | |||

| seasoning hopper capacity L (US gal) | 20 (5.3) | |||

| power consumption W (hp) | 600 (0.8) excludes any heating requirements | |||

| voltage VAC | 200 – 264 single phase | |||

| length mm (in) | 2887 (114) | |||

| width mm (in) | 1237 (49) | |||

| height mm (in) | 1768 (70) | |||

| infeed height mm (in) | 1040 (41) | |||

| weight kg (lbs) | 850 (1874) | |||

| drum capacity L (US gal) | 60 (16) | |||

| all above specifications are subject to change and may differ according to product, please confirm when placing your order. | ||||

- Other Snacks

- Pellets - dry

- Pork rinds

- Potato chips

- Tortilla chips

- Seasoning solutions

-

Ara Foods Case Study: Tropical snacks manufacturer installs TNA high-performance packaging system -

Baked Snacks brochure -

Brandneu Case Study: TNA transforms snack manufacturer’s lead time with innovative seasoning solutions -

Burton’s Biscuits Case Study: TNA helped a leading biscuit manufacturer double packaging speeds and assure quality. -

Burts Case Study: TNA helps premium snack manufacturer boost production capacity -

Cereals brochure -

Confectionery brochure -

Donkey Brands Case Study: Tortilla manufacturer doubles production with TNA -

Future Foods Case Study: Future Foods, an Egyptian snack manufacturer, prides itself on being an industry leader -

Hardbite Case Study: TNA helps gourmet chip manufacturer achieve more consistent flavour while reducing seasoning application rate -

Keystone Case Study: TNA keeps snacks food manufacturer one step ahead with turnkey packaging system -

Kingsway Confectionery: TNA helps leading confectionery packaging company accelerate growth through increased production capacity and expert technical support -

Maravilla Case Study: Snack manufacturer increases output, optimises efficiency and improves automation with TNA -

Mister Bee: TNA supports new company redesign and optimise manufuacturing facility to increase chip capacity output by 400% -

Nuts and Legumes brochure -

Pata Case Study: Italian snack manufacturer chooses integrated solutions from TNA to improve performance -

Pipers Crisps Case Study: TNA helps premium crisp manufacturer double packaging speeds and reduce waste -

Preziosi Food Case Study: Italian snack manufacturer expands portfolio with TNA’s turnkey solutions -

Riverside Foods Case Study: organic snack manufacturer doubles packaging speeds with integrated turnkey solutions from TNA -

Simplot Australia Case Study: tna roflo gateless food distribution solutions into the frozen food market -

Snacks brochure -

TNA food technology centre -

TNA helped Frimax restore production back to full capacity -

Whitby Seafoods Case Study: TNA helps frozen seafood manufacturer to double packaging speed