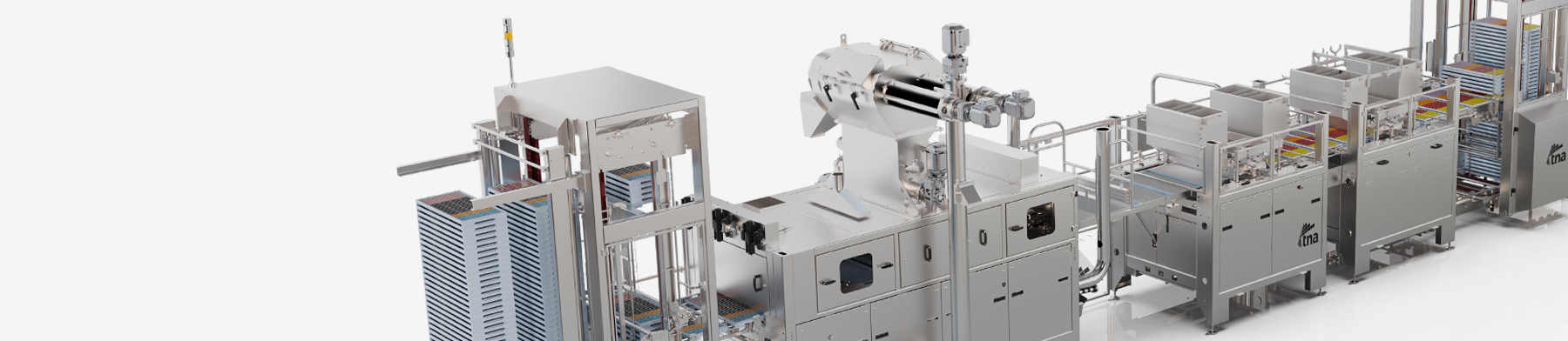

Keeping Up with Confectionery Demand: How to maximise productivity with flexible gummy processing technology

tna mogul

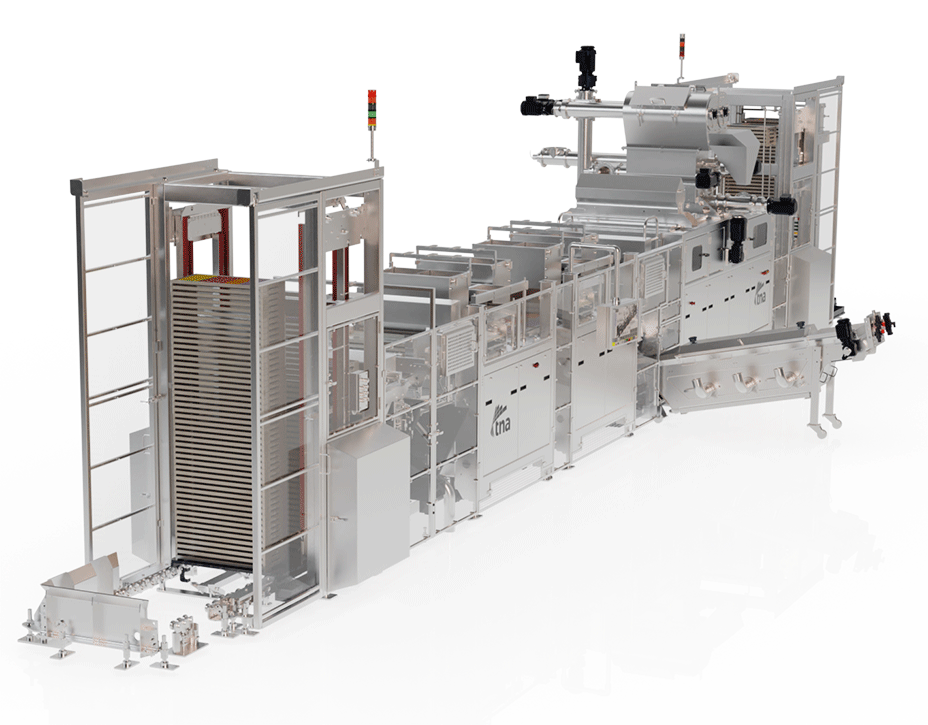

Introducing the enhanced tna mogul – the pinnacle of starch moguls, delivering industry-leading performance in crafting flawless starch-moulded confectionery around the clock. Designed for efficiency, it requires just one operator to run, reducing labour demands while maximising productivity. Recent upgrades streamline operations, minimise maintenance, enhance energy efficiency, and elevate product quality.

Crafted entirely from stainless steel for robust durability and finished with a smooth, defect-free surface that guarantees unparalleled cleanliness, this ATEX-compliant design meets the highest food hygiene and safety standards.

endless possibilities

Output capacity

– tna mogul ST up to 3200 kg/hour* output.

– tna mogul MX up to 4500 kg/hour* outputReduced waste: Enhanced inset doors, improved seals, and a powerful dust extraction system work together to contain starch and keep your line cleaner.

Starch control: Redesigned starch buck with advanced sensors ensures precise filling and automatically adjusts to volume changes -reducing operator intervention and improving containment.

Automated operation: Self-running system requires only one operator for supervision – reducing labour costs and freeing up resources for higher-value tasks.

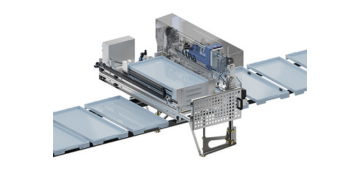

Precision printing: High-frequency technology delivers exceptional accuracy at the printing table, ensuring beauitfully detailed mould designs every time.

Safe & hygienic: Smooth detect-free stainless-steel surface for optimal cleanliness, the ATEX compliant design meets the highest food hygiene and safety standards.

Endless Possibilities: Up to 3 depositor pumps can be installed in your tna mogul allowing you to create any combination of products - single-colour, two-colour, three-colour, centre-fill, and layered gummies.

*Output subject to product type, mass and shape

- Available product models

– tna mogul ST up to 3200 kg/hour* output.

– tna mogul MX up to 4500 kg/hour* output - Up to 35 trays per minute:

– tna mogul ST max. tray size 820mm

– tna mogul MX max. tray size 1220mm - Stacker and feeder up to 70 trays each. Customisable options available. Operator safe.

- Engineered entirely with stainless steel for durability with a smooth detect-free surface for unparalleled cleanliness.

- Intelligent starch management system ensures efficient starch distribution while minimising waste and airborne dust accumulation.

- Single-touch HMI controls and simplified configuration, boosting efficiency and reducing errors.

- Advanced starch circulation, with intelligent level sensors, delivers more precise filling and increased process stability.

- With high-frequency technology, the printer delivers precision in the printing table, producing highly detailed mould designs.

- ATEX compliant design meets the highest health and safety standards.

- Install up to 3 depositor pumps for single-colour, two-colour, three-colour, centre-fill, and layered gummies.

*Capacity subject to starch material, product type, shape and mass.

Optional integrations

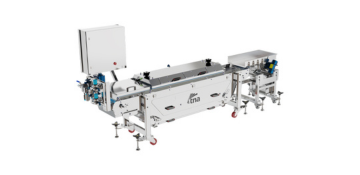

- tna conti-oil oiling system for jelly and gum-based confectioneries.

- tna conti-clean starch removal system.

- tna conti-coat sugar sanding system with integrated steamer and sugar-sander.

Depositor pumps

Upto 3 depositors of any combination can be installed in your tna mogul

- Standard / Foam Maxi depositor

- Side-by-side depositor

- Universal depositor

- Tray Insert Eject: allows for inserting and ejecting trays from the line without stopping the machine.

- Nylon Chain Box: longer lasting and robust feeder/stacker upgrade for legacy mogul systems.

- Servo Drive Upgrade: replaces legacy mechanical lever system.

- Tray Cleaning Upgrade: prevents spillage and maintains system cleanliness.

- Depositing Station: allows modular expansion of additional depositor pumps.

- Feeder and Stacker Tray Magazine Spring System: improves precision of tray positioning at different tray speeds.

For details on parts, options, and ordering, contact your local TNA office.

- Gummies & jellies

- Confectionery processing

side by side

side by side  aerated

aerated  centre-fill

centre-fill  striped

striped  double layer striped

double layer striped  double layer double colour centre-fill

double layer double colour centre-fill  triple layer single colour

triple layer single colour  triple layer single colour side-by-side

triple layer single colour side-by-side  nutraceuticals

nutraceuticals