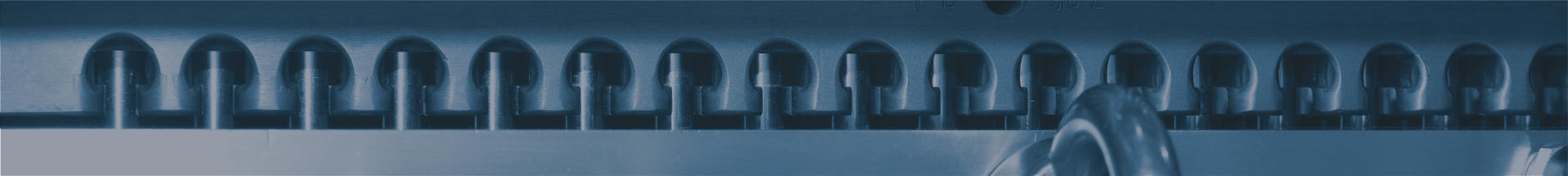

NID supra-fin SC 3

The NID supra-finSC 3 delivers consistent sugar coating of starch moulded jelly and gum-based confectionery for a truly homogenous finish. This continuous sugar-sanding system features a steaming conveyor and sugar sanding drum that can be fully integrated into a mogul confectionery processing line, delivering capacities of up to 3,600 kg/hr (7,930 lbs/hr).

Steam product surfaces as the product is transported into the coating drum.

Accurate and precise sugar delivery with controllable screw conveyor

Sugar dust control with available suction hoods

Lower sugar moisture and increase runtime in the drum.

Empty sugar quickly with reversible discharge drum drive.

Operate from an easy-to-use electrical control panel.

standard features

- Steam jets with independent control, above and below steam jets

- Manual valves to regulate steam

- Auto shut off valve for steam

- Exhaust fan for steam

- Chain-guided, stainless-steel wire mesh belt, 500 mm (19.6 in) wide

- Adjustable belt speed

- Stainless-steel steaming conveyor and stainless-steel drum

- Twin drum design, innovated by NID, for automatic recirculation of sugar

- Sugar hopper mounted on drum with easy-access pivot hinge

- Adjustable vibratory feeder (delivers sugar to the drum)

- High-efficiency contra-flow sugar-circulation curtain

- Hot air delivery into the drum with variable temperature control and fan speed control

- Product supply input sensor (on the steaming conveyor)

optional features

- Adjustable, vibratory product feeder to evenly spread out product

- Output steaming conveyor

| NID supra+A30:F45-fin SC 3 | |

|---|---|

| drum section | |

| product output kg/hr (lbs/hr) | up to 3200 (7056) |

| weight kg (lb) | 600 (1323) |

| width mm (in) | 1200 (47) |

| length allowing for sugar hopper swing mm (in) | 2300 (90.5) |

| sugar hopper capacity liters/kg (gal/lb) | 85 / 75 (22.5 / 165) |

| speed rpm | 19 |

| electrical requirements kW (hp) | 9.5 (12.75) |

| input steaming conveyor section | |

| weight kg (lb) | 260 (573) |

| width mm (in) | 1025 (40.35) |

| steam supply pressure bar (psi) | 4 (58) |

| approx. steam consumption kg/hr | 600 (1323) |

| electrical requirements kW (hp) | 3 (4) |

| vibratory feeder-spreader section | |

| weight kg (lb) | 280 (617) |

| electrical requirements kW (hp) | 0.5 (0.7) |

| all above specifications are subject to change and may differ according to the product, please confirm when placing your order. | |

- gummies & jellies

- confectionery processing

-

Ara Foods Case Study: Tropical snacks manufacturer installs TNA high-performance packaging system -

Brandneu Case Study: TNA transforms snack manufacturer’s lead time with innovative seasoning solutions -

Burton’s Biscuits Case Study: TNA helped a leading biscuit manufacturer double packaging speeds and assure quality. -

Burts Case Study: TNA helps premium snack manufacturer boost production capacity -

Confectionery brochure -

Donkey Brands Case Study: Tortilla manufacturer doubles production with TNA -

Future Foods Case Study: Future Foods, an Egyptian snack manufacturer, prides itself on being an industry leader -

Hardbite Case Study: TNA helps gourmet chip manufacturer achieve more consistent flavour while reducing seasoning application rate -

Keystone Case Study: TNA keeps snacks food manufacturer one step ahead with turnkey packaging system -

Kingsway Confectionery: TNA helps leading confectionery packaging company accelerate growth through increased production capacity and expert technical support -

Maravilla Case Study: Snack manufacturer increases output, optimises efficiency and improves automation with TNA -

Mister Bee: TNA supports new company redesign and optimise manufuacturing facility to increase chip capacity output by 400% -

Pata Case Study: Italian snack manufacturer chooses integrated solutions from TNA to improve performance -

Pipers Crisps Case Study: TNA helps premium crisp manufacturer double packaging speeds and reduce waste -

Preziosi Food Case Study: Italian snack manufacturer expands portfolio with TNA’s turnkey solutions -

Riverside Foods Case Study: organic snack manufacturer doubles packaging speeds with integrated turnkey solutions from TNA -

Simplot Australia Case Study: tna roflo gateless food distribution solutions into the frozen food market -

TNA helped Frimax restore production back to full capacity -

Whitby Seafoods Case Study: TNA helps frozen seafood manufacturer to double packaging speed