Improve efficiencies, increase yield & reduce product wastage

tna ultra-cleanCOMBO 3

The tna ultra-cleanCOMBO 3 is a highly efficient, 3-in-1 cleaning solution for de-soiling, de-stoning and washing root vegetables, including potatoes. With a small footprint, it is the ideal addition to smaller production lines, positioned ahead of your chosen peeling system. Plus, the simple yet robust design of the rotary drum destoner and washer makes it easy to maintain and operate – for reduced downtime.

tna ultra-cleanOC 3

A continuous vegetable destoner, the tna ultra-cleanOC 3 uses a cyclone effect to ensure the efficient removal of stones and soil from root vegetables, including potatoes. The funnel-shaped hopper is filled with spinning water to allow the root vegetables to rise to the top, forcing the stones to separate and sink to the bottom. Pair with the tna ultra-cleanWT 3 for a complete cleaning system that helps optimise production lines – even at high-capacities.

tna ultra-cleanWT 3

Designed for maximum efficiency, the tna ultra-cleanWT 3 removes clay shells, sand and soil from potatoes and other root vegetables – without damage. The drum washer system combines with the tna ultra-cleanOC 3 to form a complete cleaning solution, well-suited to high-capacity lines. Thanks to its simple design, the tna ultra-cleanWT 3 requires little maintenance, helping to reduce production downtime.

tna ultra-peelSKC 3

Ensure accurate peeling with the tna ultra-peelSKC 3. This abrasive peeler skins potatoes and other root vegetables in batches, by using weighing technology to ensure optimum peeling results – whatever the product size. Featuring a single, double or triple configuration, the system offers flexibility to meet specific capacity requirements. Simple to operate, the tna ultra-peelSKC 3 has fewer moving parts, for increased reliability.

tna hydro-washWTP 3

This potato slice washing system, or as it’s better known – the tna hydro-washWTP 3 – removes starch to prevent potato slices from sticking together. In addition, it collects only full-size potato slices and places them in a single layer for even frying. Perfect for smaller capacity production lines, this system is always reliable.

tna hydro-washSW 3

The tna hydro-washSW 3 is an advanced potato slice washing system that removes starch to prevent potato slices from sticking together. In addition, it only collects full-size potato slices and places them in a single layer for even frying. Perfect for larger capacity production lines, this machine is always reliable.

tna thermo-washHW 3

The tna thermo-washHW 3 is a potato hot washing system designed to overcome challenges associated with raw materials high in sugar, by lowering sugar content to below 0.2% ready for frying. Ensuring little-to-no discolouration or brown spots of potato slices, the tna thermo-washHW 3 helps you to deliver a high-quality product every time.

tna hydro-clearOWB 3

A highly efficient potato dewatering system, the tna hydro-clearOWB 3 removes water from both sides of potato slices before frying, while ensuring products are evenly spaced. By eliminating excess water, the equipment reduces oil heating and product retention times to lower the fryer’s energy consumption.

tna batch pro 12

Choose the tna batch-pro 12 for highly efficient batch frying of a wide selection of vegetable chips, including potato, taro, banana and plantain. Featuring a serpentine heat exchanger tube configuration, the batch fryer system provides direct-fire heating for improved energy efficiencies and lower operating costs. Thanks to its high-speed, three-stage oil filtration system, the tna batch-pro 12 extends oil life and maintains product consistency too. In addition, an automatic stirrer eliminates racking and prevents damage to the internal transport system.

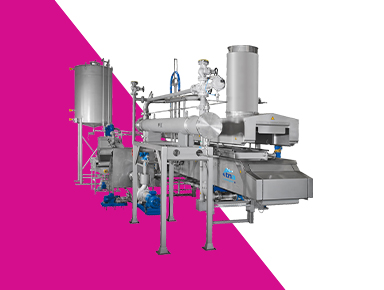

tna conti-proPC 3

Designed especially for potato chips, the tna conti-proPC 3 is a high-performance continuous frying system. Featuring patented opti-flow® technology, this atmospheric fryer optimises oil and product flow to produce evenly fried potato chips – every time. Plus, with a multi-flow oil injection system and automatic temperature control, the tna conti-proPC 3 allows you to adjust your frying process quickly and easily for consistent potato chip texture and quality.

tna vac-pro 3

Consistently produce high-quality fried products with lower fat content by choosing the tna vac-pro 3. Suitable for a wide range of root vegetables and fruits, the continuous vacuum fryer operates at lower temperatures to reduce oil absorption, while also minimising acrylamide formation – no matter the sugar content of the raw materials. The result: a healthier product with more natural colour, taste and texture.

tna roflo®VM 3

The tna roflo®VM 3 is a high-performance food conveyor system that uses horizontal vibratory motion to evenly distribute products, while offering an efficient method for in-line storage. Its versatile design features a variety of pan options to suit every production need.

tna roflo®HM 3

The tna roflo®HM 3 is a high-performance food conveyor system that handles products gently, yet efficiently, using a slow, forward horizontal motion, followed by a fast return horizontal motion. With no vertical element, this system minimises flavour loss and reduces seasoning build-up in the pan – making it an ideal transport solution for heavily-coated products.

tna roflo®VMBS 3

The tna roflo® VMBS 3 is a compact vibratory motion blending system that accurately measures individual ingredients to ensure every recipe is a success. Using speed, vertical motion and mass flow technology, its innovative design regulates the amount and distribution of dry/wet ingredients to create a perfectly proportioned mix.

Thanks to its modular design, this simple and flexible blending system works with just about any production layout, while offering a small plant footprint. And with fewer moving parts, less maintenance and energy are required.

tna roflo®VMCS 3

The tna roflo®VMCS 3 is a compact vibratory motion blending system that accurately measures individual ingredients to ensure every recipe is a success. Using speed, vertical motion and mass flow technology, its innovative design regulates the amount and distribution of dry/wet ingredients to create a perfectly proportioned mix.

Thanks to its modular design, this simple and flexible blending system works with just about any production layout, while offering a small plant footprint. And with fewer moving parts, less maintenance and energy are required.

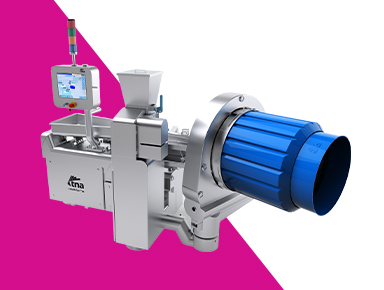

tna robag®FX 3e

tna robag®FX 3e is a high-performance vertical form fill and seal (VFFS) packaging system that delivers the fastest speeds in the industry and the latest in automation with real-time EtherCAT® protocol.

Reaching up to 250 bags per minute*, the tna robag®FX 3e also offers superior flexibility thanks to its rotary triple, double, single and flat jaw configurations. With an integrated display controller CXE, smart diagnostics system, and enhanced serviceability, the tna robag®FX 3e bags just about any type of snack (or food application) faster and more efficiently than anyone else.

tna auto-splice 3

The tna auto-splice 3 system is an innovative solution that automatically joins a new film to an expiring film roll with no interruption to packaging line. Featuring a dual-spindle film system and rotary reel swapping mechanisms, a new pre-prepared film is always ready to take over from the current roll. This helps reduce film waste and removes the downtime associated with manually splicing and replacing rolls, increasing uptime by up to 5%*. The result; a more productive and profitable packaging line, capable of producing up to 2,800 more bags per line, per day*.

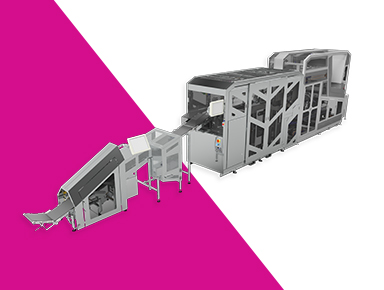

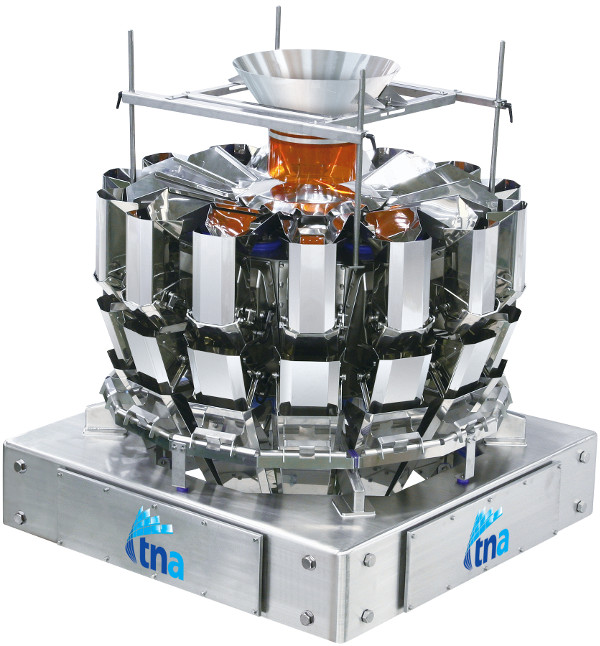

tna intelli-weigh® omega series

Simplify weighing processes for both wet and dry applications with the tna intelli-weigh® omega series. With a stainless-steel construction and waterproof scales, these efficient multi-head weighers offer an advanced hygienic design that goes beyond industry standards to ensure seamless maintenance and quick product changeovers. The series is eco-friendly too, helping to reduce product waste, while its simple structure requires fewer parts that need changing due to wear and tear. In addition, a modular actuator unit provides quick troubleshooting, when needed.

tna intelli-weigh® alpha advance series

The tna intelli-weigh® alpha advance series of multi-head weighers is a simple, affordable weighing solution that does not compromise performance or efficiency. Suitable for dry applications, it features a 10.4″ colour touchscreen for seamless operation, while its streamlined design with fewer moving parts and specially designed radius corner buckets, makes it easy to maintain and clean for faster product changeovers.

tna hyper-detect® 5

Protect your brand’s reputation with the tna hyper-detect® 5. This high-performance food metal detector system is uniquely designed to sit as close as possible to the multi-head weigher, significantly increasing bagging speed without compromising food safety. The tna hyper-detect® 5 is ultra-sensitive, detecting ferrous contaminants from 0.8mm to 0.9mm, non-ferrous pieces down to 1.0mm, and non-magnetic stainless steel from 1.0mm to 1.2mm.

tna intelli-detect® 3

Protect your product from contamination with the tna intelli-detect® 3 – a highly accurate throat metal detector specially designed to detect contaminants of less than 0.5mm in diameter, in addition to any metals. These include including ferrous, non-ferrous and non-magnetic stainless steels (grade 316). In addition, the tna intelli-detect® 3 integrates seamlessly with any VFFS packaging system

tna intelli-date® 5

The tna intelli-date® 5 is a smart thermal transfer overprint (TTO) date coder, designed to improve uptime and productivity through the reduction of waste and rejects. The system features innovative technology, including an airless all-electronic system, integrated code defect detection and easy-to-change ribbon drive.

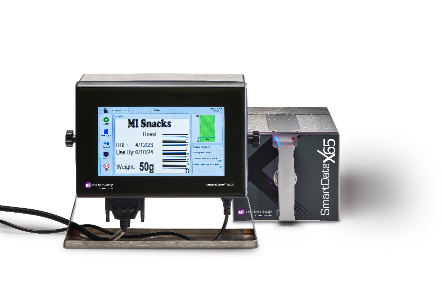

tna smartdate® x60

The tna smartdate® x60 is an innovatively designed high performance date coder that applies date codes and/or batch codes accurately and clearly using high-quality print. With high-resolution thermal transfer technology and a unique electronic ribbon drive system, the system prints on moving packaging films, increasing production uptime.

tna smartdate® x65

The tna smartdate® X65 is an advanced high-performance date coder that uses thermal transfer technology and an electronic ribbon drive to print date codes accurately and consistently on flexible film packs. This system is designed to suit even the most demanding, high-volume applications. Capable of delivering up to 455 packs per minute, it is supported by an intuitive 10.1” touch-screen display and features a unique tracking and reporting function to help boost OEE. The tna smartdate® X65 also includes an optional smart-date detect-plus verification system that is ideal for removing faulty codes and safeguarding your brand.

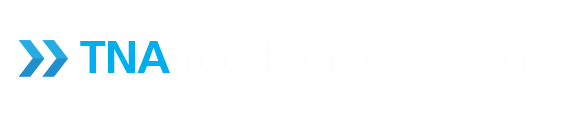

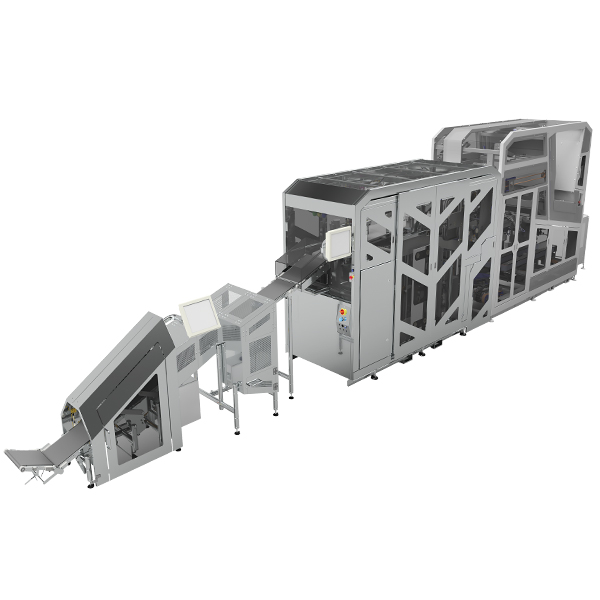

tna ropac® 5

The world’s fastest case-packing system for flexible bags capable of packing up to 200 bags per minute. Using TNA’s own patented semi-rotary technology, the tna ropac® 5 case packer is designed to pack small-to-medium, pillow style snack bags. Most bag widths and lengths are handled with ease for packing various applications such as snacks, confectionery, pasta and cereal.

Production efficiency, oil filtration and product quality

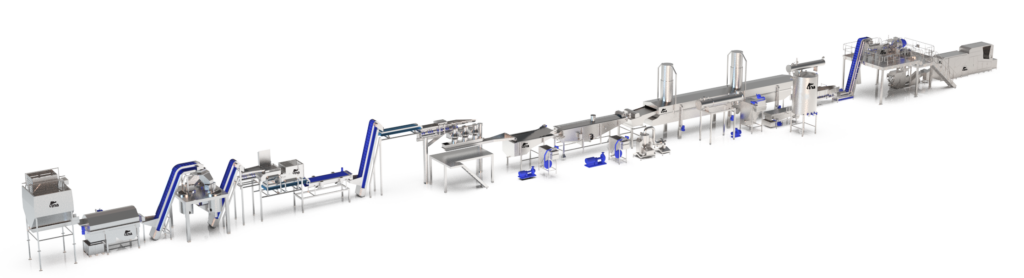

Experience the following benefits with TNA’s potato chip processing solutions:

- Greater production efficiency: Leverage innovative technology and get more control over the process while increasing yield and product quality. Achieve a more efficient process and optimised product output, leading to higher quality end-products and less resource waste.

- Enhanced frying process: TNA’s frying solutions are equipped with laminar oil flow technology to improve control over the frying process. Combined with continuous debris removal systems, our solutions extend the quality and lifetime of the frying oil for better quality product and reduced resource spending.