TNA is the only global partner offering both complete and integrated solutions, purpose-built to help you continually innovate and accelerate your business.

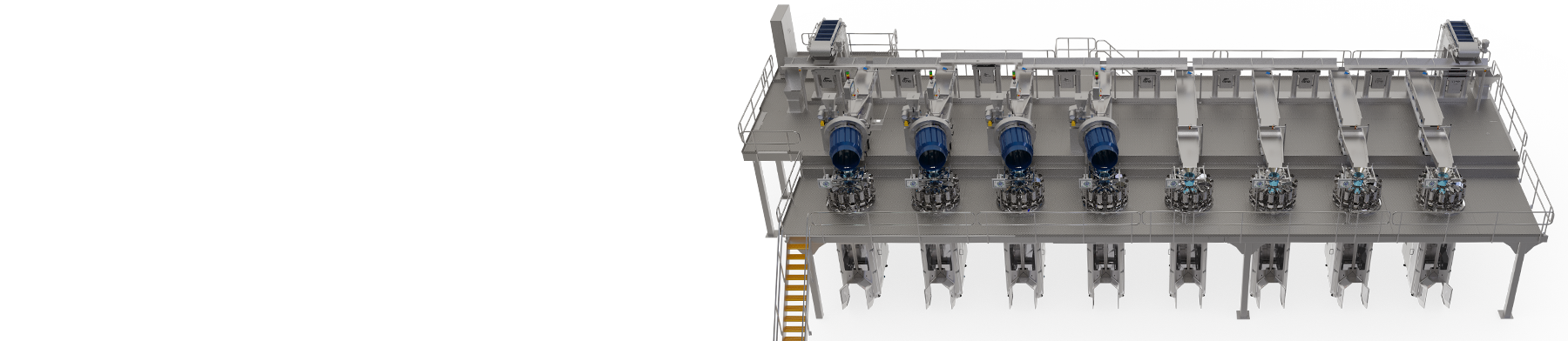

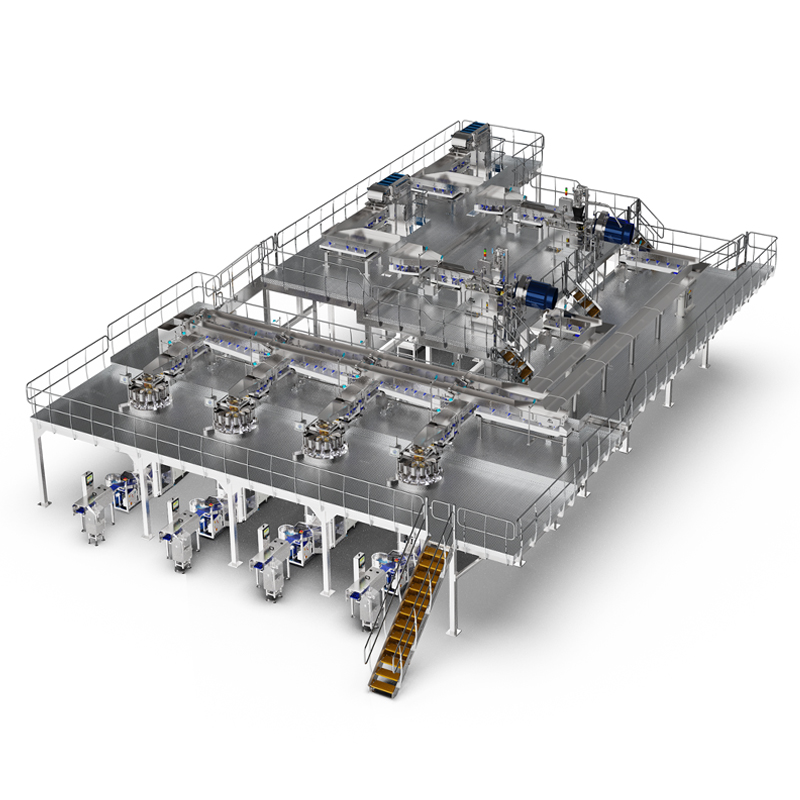

The integration across seasoning, distribution and packaging optimises the entire line by connecting the individual systems into a cohesive, efficient flow — enhancing throughput, reducing waste, and ensuring consistent, high-quality output. It also streamlines operations, cuts installation time and maintenance costs, and minimises downtime for a stronger return on investment.

Intelligent integrated system

- Optimised efficiency

The intelligent, integrated system ensures smooth and continuous product flow, maintaining maximum line efficiency. - Perfect seasoning

Seamless integration between the tna robag® and tna intelli-flav® enables precise, recipe-driven product flow — dynamically adjusting seasoning levels to maintain optimal seasoning coverage. - Perfect scale feed

Integration between the tna roflo® VM and tna robag® allows dynamic product transfer to the weighing scales, automatically adjusting the conveyor’s vibratory amplitude for optimal flow. - Enhanced horizontal conveying

The tna roflo® HM can intelligently adjust product flow (kg/hr) to ensure smooth and continuous product flow. - Unified interface

TNA systems feature a harmonised menu across the entire line, reducing operator training time and user error. - Guaranteed accountability

Partnering with TNA streamlines installation and support, eliminating the need to manage multiple vendors. We take full responsibility, ensuring prompt issue resolution and world-class service.

integrated system range

Together, these individual systems form a single cohesive and efficient line that enhances overall throughput, reduces waste, and ensures high-quality, consistent products.

tna robag® FX 3e

Boost productivity and operational efficiency with the fastest and most efficient VFFS packaging system on the market. Renowned for unparalleled engineering standards and world-first innovations the tna robag® 3e is capable of 250* bags per minute with over 95% efficiency. Available in a wide range of configurations to suit the needs of your production line.

tna roflo® HM 3

Our tna roflo® HM 3 is a conveyor system that uses horizontal motion distribution that outperforms other industrial conveyor systems. Its patented gateless design and gentle sweeping motion drive efficiencies while reducing product breakage and seasoning loss. Further, the tna roflo® HM 3 offers easy cleaning and minimal seasoning build-up thanks to its quick-release pans. For products that are heavily coated, the tna roflo® HM 3 is an optimal solution.

tna roflo® VM 3

Our tna roflo® VM 3 is a conveyor system that uses vibratory motion technology to quickly and evenly distribute products without compromising on handling. Its patented design offers in-line storage and a variety of pan options to suit even the most niche production needs.

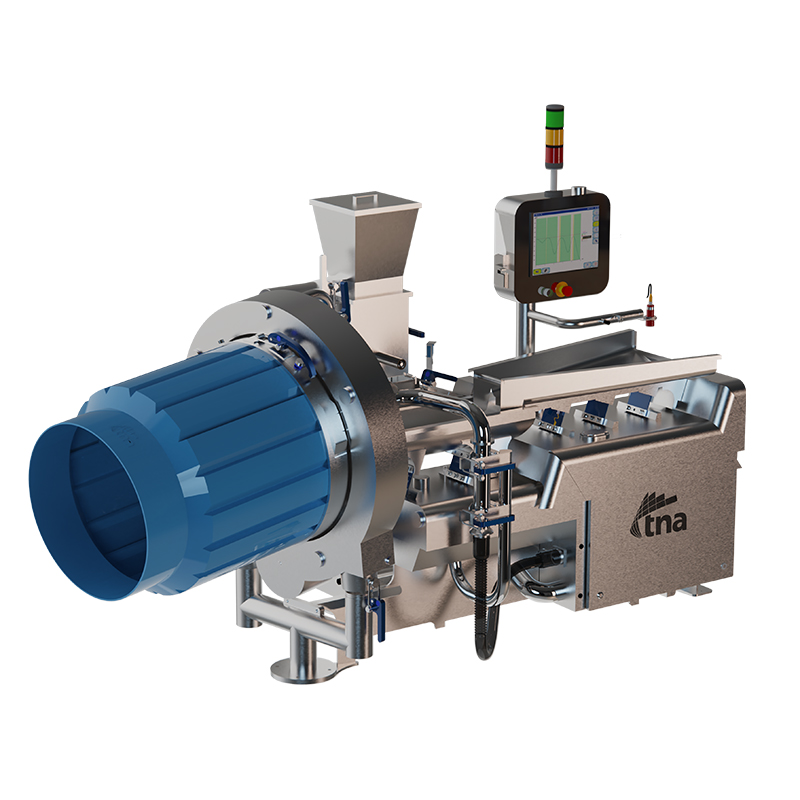

tna intelli-flav® OMS 5

Uses a single, high-speed tumbler drum to apply a range of wet, dry and slurry seasonings to numerous hot and cold product types. Minimise seasoning waste and deliver consistent product flavour, texture and appearance to customers.

tna intelli-flav® OMS 5.1

Adds an additional layer of functionality to the tna intelli-flav OMS 5. This system is equipped with an optional high-capacity stainless-steel drum and integrated heated oil circulation system to enable a much wider product seasoning range.

tna intelli-flav® MLS 3

Our extensive selection of advanced seasoning solutions helps you optimise processing times, increase production output and boost your equipment ROI at the lowest cost of ownership. Carefully and accurately spreads dry and wet flavourings across a diverse range of products for a consistent texture and flavour profile. Gravimetric control technology enables complete command of seasoning processes for reduced wastage.