TNA is the leading provider of innovative packaging solutions to businesses and manufacturers across the world for more than four decades.

Our wide range of food packaging solutions help you maximise your production output, reduce resource wastage and deliver consistently high-quality bagged food items.

Equipped with TNA’s patented packaging technology, each of our packaging machines can be integrated with tna Intelli-flav seasoning solutions, tna Roflo distribution systems and tna Ropac 5 case packers for a seamless production line.

helping you enhance your packaging system

Our food packaging equipment is built with patented technology to help you deliver high performance and quality output no matter your product type.

*Depending on bag size and food product type

tna robag® 3e

tna auto-splice 3

tna ropac® 5

tna arctic® 3

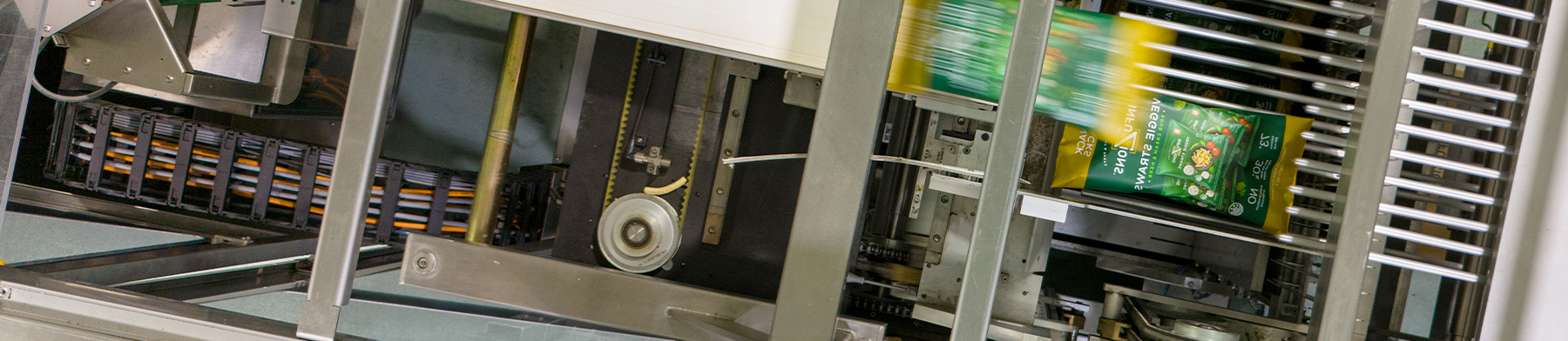

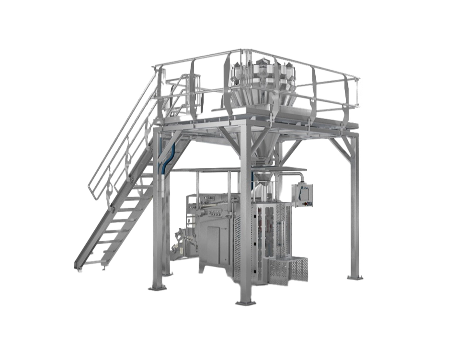

tna robag® 3e

tna robag® 3e is the fastest solution currently available on the food packaging equipment market. Capable of bagging up to 250 packs per minute,* the tna robag® FX 3e provides world-class efficiency and reliability in a single, automated solution. Equipped with an integrated display controller CXE and a smart diagnostics system, the tna robag® FX 3e can package snack food items of all kinds, making it capable of being finely tailored to meet the specific needs of your production line.

tna auto-splice 3

Built on a patented design featuring dual-spindle film systems and rotary reel swapping mechanisms, the tna auto-splice 3 automatically replaces an expiring film roll with a new film to ensure seamless packaging line operations. auto-splice 3 integrates seamlessly with each of our robag systems to increase system uptime, optimise packaging processes and improve overall production performance. When retrofitted to our robag machines, auto-splice 3 adds only 200mm to the broader packaging apparatus for a compact design that minimises floor space usage.

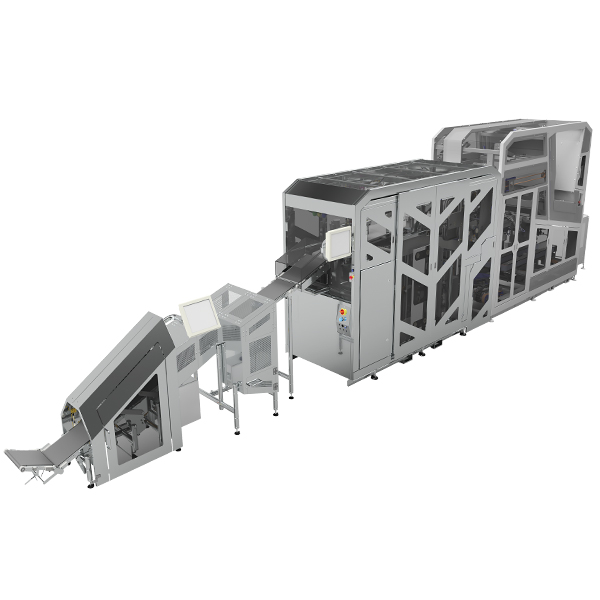

tna ropac® 5

The tna ropac® 5 provides businesses and manufacturers with the production capacity to pack pillow-style snack bags ranging from small to medium sized. Capable of bagging up to 220 products per minute,* the tna ropac® 5 is built with our patented semi-rotary technology to facilitate a high degree of flexibility based on your production requirements. The tna ropac® 5 system can handle bags of all widths and lengths and covers a variety of, including snacks, pastas, cereals and confectionery items.

Learn more

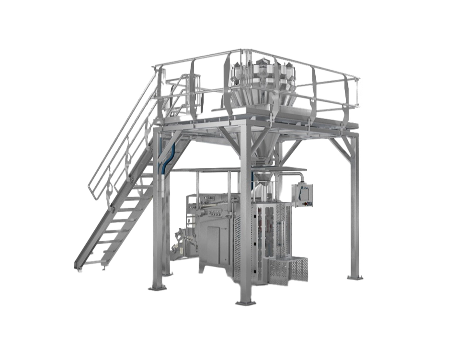

tna arctic® 3

A vertical form, fill and seal (VFFS) food packaging solution, the tna arctic®3 is constructed from anti-corrosive stainless steel, handles wet washdown cleaning and meets strict sanitary requirements. All to produce high-quality bags using polyethylene and laminated films for your fresh and frozen food packaging needs. It also promises simplicity with software that holds pre-set recipes for easier set-up.

barcode verification system

We offer businesses a wide selection of advanced barcode verification systems to help them easily track, verify and record all products passing through their production lines. We take the guesswork out of food packaging.

access the industry’s most innovative barcode verification systems

Each of our manufacturing solutions is built with our patented, cutting-edge technology to facilitate barcode verification functions across a comprehensive range of food products.

Our barcode verification solutions include:

help

tna intelli-read 3

tna smart-date X60

tna intelli-scan 2

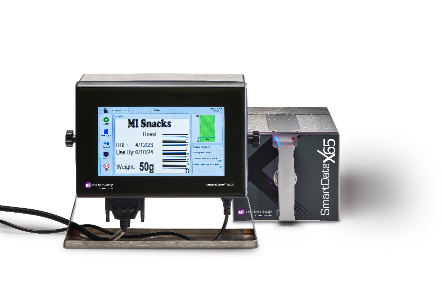

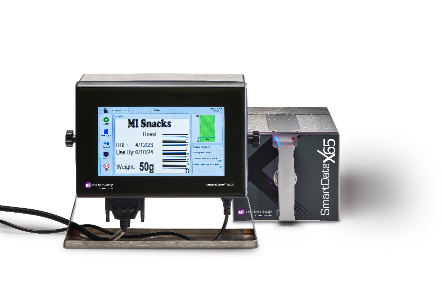

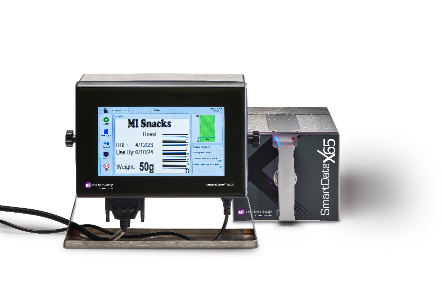

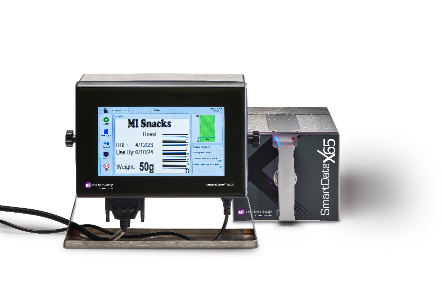

tna smart-date x65

tna intelli-date 5

tna intelli-read 3

This advanced scanning system is equipped with a web-width barcode verification system to automatically read products passing through the production line. tna intelli-read 3 seamlessly integrates with other TNA machines (including our robag packaging system) to ensure seamless manufacturing operations.

tna smart-date X60

Our premium date coder uses high-resolution thermal technology and an industry-leading ribbon drive system to apply extremely accurate date and batch codes to product packaging designs. Capable of printing on moving packages, the tna smart-date X60 minimises system downtime for increased operational efficiency.

tna intelli-scan 2

Equipped with a high-speed image detection system, our tna intelli-scan 2 product determines whether every food item leaving the production line adheres to the highest barcode quality standards. intelli-scan 2 works at an accelerated capacity, enabling the system to quickly identify miscoded or uncoded products for recoding.

tna smart-date x65

Our most sophisticated date coder system, the tna smart-date X65 uses the industry’s most advanced thermal transfer technology to handle coding functions for products across a range of applications. This solution is able to deliver up to 455 packs per minute,* optimising throughput capacities for a more productive manufacturing line.

tna intelli-date 5

This advanced scanning system is equipped with a web-width barcode verification system to automatically read products passing through the production line. tna intelli-read 3 seamlessly integrates with other TNA machines (including our robag packaging system) to ensure seamless manufacturing operations.

improve output, enhance efficiency, increase ROI

We are the manufacturing equipment provider of choice for businesses across the world. We’re committed to supplying the most innovative solutions to help you achieve your loftiest business objectives.

Some of the benefits of deploying TNA’s barcode verification systems

Improving production output:

Each of our barcode verifier and scanner systems is capable of handling a significant volume of packaged products at high speeds while maintaining your high barcode quality standards. This helps you increase your production capacity without increasing your operating costs.

Enhancing operational efficiency:

Our barcode scanner and verifier systems are equipped with our highly advanced, patented technology to facilitate accurate processing of all products for much higher operational efficiency. Our solutions minimise the incidence of mistakes, resulting in less system downtime and more consistent production outcomes.

Increasing profits:

In addition to increasing production output and boosting operational efficiency, our verification, dating and scanning systems reduce resource wastage, optimising your manufacturing budget. Integrations with other TNA products create a seamless production line for further cost savings.

food packaging metal detectors

Our food packaging metal detectors empower businesses and manufacturers of all sizes to deliver consistently clean, safe and high-quality products. We help you enhance production efficiency to enable high-performance across your entire production line.

enhancing food quality with tna

Businesses have entrusted us to provide them with high performance food metal detectors for more than 40 years. Our products are designed to drive manufacturing excellence through fully customisable features and designs that match the unique needs of your business. Our patented metal detection technology facilitates the delivery of clean, high-quality products to customers on a consistent basis.

We are also committed to supporting your sustainability objectives by providing manufacturing solutions that help you lower your carbon footprint while continuing to deliver value to your customers.

tna’s food packaging and metal detection solutions

Our selection of food packaging metal detectors include:

tna intelli-detect 3

tna hyper-detect 5

tna’s intelli-detect 3 is equipped with a highly accurate throat metal detection system that is capable of alerting operators to contaminants less than 0.5mm in diameter. While this detection system is equipped to handle all ferrous contaminants, it is also able to identify other foreign objects, such as non-ferrous and non-magnetic stainless steel particles (grade 316). Some of the advantages you can experience with tna Intelli-detect 3 include:

tna hyper-detect 5 is built with sophisticated detection sensitivity systems to pinpoint and remove ferrous metal contaminants ranging in diameter from 0.8mm to 0.9mm. It’s also capable of alerting you to non-ferrous particles at diameters as small as 1.0mm, while detecting non-magnetic stainless steel pieces ranging from 1.0mm to 1.2mm in diameter.

The product’s in-built metal detection system is also purposely designed to sit close to the multi-head weigher, increasing bagging speed while maintaining high levels of food safety.

Some of the benefits your operations can experience using hyper-detect 5 include:

using tna’s solutions to improve product quality and consistency

Our metal detection solutions can benefit your company or manufacturing plant in the following ways:

Safeguarding your brand’s reputational security:

Food contamination can do serious harm to your brand’s image and reputation. In addition to regulation penalties, consumers might lose trust in your ability to deliver quality products. Our industry-leading metal detection systems help you produce clean, contaminant-free products on a consistent basis, to ensure your customers get only the safest and highest quality food product.

Improving the sustainability of your plant:

All of our metal detection systems are built with a compact design that makes them easy to install and position in your plant, without requiring excess floorspace. This helps to improve the efficiency of your business, leading to less energy and resource waste and more sustainable food production processes.

Promoting system uptime through product integration:

Promoting system uptime through product integration: TNA’s manufacturing products are each designed with full integration capabilities for a complete, seamless production line from beginning to end. Integrating our metal detection solutions with our processing, packaging, finishing and other products helps you to maximise your system uptime for more efficient operations and a consistently high output volume.